Malaysia palm oil, a cornerstone of the Malaysian economy, is a globally significant commodity. From its historical role to its diverse product forms, this report explores the multifaceted landscape of the industry, examining production methods, global market dynamics, and sustainability concerns. The report delves into the complexities of palm oil cultivation, processing, and trade, providing a comprehensive overview of its economic, social, and environmental impact.

The report analyzes the current global demand for palm oil, highlighting major competitors and suppliers. It also assesses the influence of trade policies on Malaysian exports, providing a detailed look at pricing trends and key global markets. Furthermore, the report scrutinizes the methods of palm oil cultivation, focusing on environmental impact and sustainable practices, including certifications and the role of deforestation.

Overview of Malaysian Palm Oil

Malaysia’s palm oil industry, a cornerstone of the Southeast Asian economy, boasts a rich history intertwined with agricultural development and global demand. From humble beginnings, it has evolved into a multi-billion dollar sector, driving economic growth and influencing global food markets. The commodity’s prominence stems not only from its widespread use in food products but also its crucial role in biofuels and various industrial applications.

The industry’s significant economic contribution to Malaysia is undeniable, providing employment opportunities across numerous sectors and generating substantial export revenues. Understanding the different types of palm oil products and their distinct characteristics is vital for grasping the intricate workings of this vital sector.

History of Palm Oil Production in Malaysia

Palm oil production in Malaysia has a history deeply rooted in agricultural expansion and technological advancements. Early cultivation focused primarily on smallholder plantations, but as demand grew, large-scale commercial plantations emerged, leading to increased efficiency and output. This evolution, coupled with technological advancements in processing and refining, has positioned Malaysia as a global leader in palm oil production. Government policies and incentives played a significant role in encouraging and facilitating the growth of the industry.

Significance of Palm Oil to the Malaysian Economy

Palm oil’s economic significance to Malaysia is multifaceted. It serves as a vital source of export revenue, contributing substantially to the country’s foreign exchange earnings. The industry’s impact extends beyond export earnings, creating numerous employment opportunities throughout the supply chain, from plantation workers to processing plant employees and marketers. The industry’s economic ripple effect is substantial, supporting related sectors like transportation, packaging, and logistics. The sector’s influence on rural communities and overall GDP is undeniable.

Major Types of Palm Oil Products

Palm oil’s versatility extends far beyond its use in cooking. A wide array of products are derived from palm oil, ranging from food products to industrial applications. The processing methods determine the final product, impacting its physical characteristics and intended uses. The diversity of applications underscores the importance of this agricultural commodity.

Comparison of Palm Oil Varieties

| Palm Oil Variety | Description | Typical Uses |

|---|---|---|

| Crude Palm Oil (CPO) | The unrefined form of palm oil, extracted directly from the fruit. | A key ingredient in food products, including cooking oil, margarine, and shortening. It is also used in some industrial applications. |

| Refined Palm Oil | CPO undergoes a refining process to remove impurities and undesirable components. | Used in a wide array of food products, including cooking oil, spreads, and confectionery. |

| Bleached Palm Oil | Refined palm oil is further processed to remove color pigments. | Often used in food products where a clear and pale color is desired, such as margarine and shortening. |

| Bleached, Deodorized Palm Oil (BDO) | Refined and bleached palm oil is treated to remove odors and undesirable flavors. | Used in applications where a neutral flavor profile is critical, such as certain processed foods, confectionery, and cosmetics. |

Global Market Dynamics

Palm oil, a crucial ingredient in numerous food and industrial products, faces complex global market dynamics. Its production in Malaysia, a significant player, is intertwined with global demand, competitive pressures, and fluctuating trade policies. Understanding these forces is essential to assess the future of the Malaysian palm oil industry.

The global market for palm oil is characterized by substantial demand, driven by its versatility and cost-effectiveness as a cooking oil and ingredient in various processed foods. This high demand, coupled with the increasing global population and evolving consumer preferences, underscores the importance of the commodity in the international market.

Current Global Demand

Global demand for palm oil is substantial, driven by its widespread use in food products and industrial applications. The growing global population and rising incomes in developing economies are significant drivers of this demand. Moreover, the inherent cost-effectiveness of palm oil compared to other vegetable oils contributes to its sustained popularity. Forecasts suggest continued strong demand in the coming years, primarily in emerging economies.

Major Competitors and Suppliers

Malaysia faces competition from other palm oil producers, including Indonesia, and other vegetable oil suppliers. The production capacity and export strategies of these competitors influence the price and market share of Malaysian palm oil. Furthermore, the global market for vegetable oils is diverse, with various oils competing for market share based on price, quality, and sustainability considerations.

Impact of Global Trade Policies

Global trade policies, including tariffs and quotas, significantly affect Malaysian palm oil exports. Changes in trade agreements and regulations can impact the price of palm oil and access to key markets. For instance, trade disputes or restrictions imposed by certain countries can lead to disruptions in the global supply chain.

Pricing Trends

Palm oil prices have exhibited considerable volatility in recent years, influenced by factors such as supply-demand imbalances, weather patterns affecting yields, and geopolitical events. Fluctuations in crude oil prices also affect palm oil prices, as palm oil production and transportation rely on energy resources. Historical data shows periods of price spikes and crashes, highlighting the sensitivity of the market to various global forces.

Key Global Markets for Malaysian Palm Oil

The global market for Malaysian palm oil is multifaceted, with various regions exhibiting differing demand patterns. The distribution of exports is vital for understanding the industry’s market position.

| Key Global Market | Significance | Demand Drivers |

|---|---|---|

| China | Largest import market | High population, diverse food industry |

| India | Significant import market | High consumption of cooking oil, large population |

| Europe | Growing demand for sustainable palm oil | Consumer preference for environmentally conscious products |

| North America | Moderate import market | Food processing and industrial applications |

| Southeast Asia | Regional demand, including processed food | Local consumption and industrial use |

Production and Sustainability

Malaysia’s palm oil industry, a vital component of the global supply chain, faces scrutiny regarding its environmental impact. The sheer scale of production, coupled with the demand for sustainable alternatives, necessitates a comprehensive understanding of the cultivation methods, environmental footprint, and certification programs employed. This examination will explore the challenges and opportunities inherent in achieving sustainable palm oil production.

Palm Oil Cultivation Methods

The Malaysian palm oil industry utilizes large-scale plantations, often involving clearing of existing forests and vegetation. Traditional methods focus on maximizing yields through intensive agricultural practices, including the application of fertilizers and pesticides. Modern techniques, however, are increasingly adopting precision agriculture, employing satellite imagery and data analytics to optimize resource use and minimize environmental impact. The transition toward these methods, while promising, is ongoing and varies considerably across different plantations.

Environmental Impact of Palm Oil Production

The environmental impact of palm oil production is multifaceted and significant. Deforestation, a critical issue, leads to biodiversity loss, soil erosion, and greenhouse gas emissions. Conversion of natural habitats for palm oil plantations disrupts ecosystems, impacting local communities and wildlife. Further, the use of fertilizers and pesticides, while necessary for yield enhancement, can contribute to water pollution and harm non-target organisms. The industry is actively working to mitigate these negative impacts through the implementation of sustainable practices.

Sustainable Palm Oil Certification Programs

Various certification programs aim to ensure sustainable palm oil production. These programs, including the Roundtable on Sustainable Palm Oil (RSPO), aim to standardize practices, encourage responsible land use, and promote environmentally sound farming methods. RSPO certification standards typically address deforestation prevention, biodiversity conservation, and community engagement. These certifications provide consumers with a means to identify and choose sustainably produced palm oil.

Role of Deforestation in Palm Oil Production

Deforestation plays a crucial role in palm oil production, as clearing land for plantations is a necessary step. The conversion of forests and peatlands to palm oil estates has resulted in significant biodiversity loss and greenhouse gas emissions. Deforestation can lead to irreversible damage to ecosystems, threatening the survival of numerous species and altering local climates. The industry faces immense pressure to reduce deforestation and adopt more sustainable land management strategies.

Comparison of Sustainable and Conventional Palm Oil Production Methods, Malaysia palm

| Characteristic | Conventional Palm Oil Production | Sustainable Palm Oil Production |

|---|---|---|

| Land Clearing | Often involves deforestation of natural habitats. | Prioritizes reforestation, minimal deforestation, and land rehabilitation. |

| Biodiversity Impact | Significant loss of biodiversity due to habitat destruction. | Aims to conserve biodiversity by preserving existing habitats and promoting biodiversity-friendly practices. |

| Greenhouse Gas Emissions | High emissions due to deforestation and land conversion. | Reduced emissions through sustainable practices and carbon sequestration strategies. |

| Water Usage | High water consumption from irrigation, often exceeding the natural water cycle. | Efficient water management strategies are employed to reduce water footprint. |

| Certification | No formal certification. | Adheres to specific standards, like RSPO, for verifiable sustainability. |

Challenges and Opportunities

The Malaysian palm oil industry, a cornerstone of the nation’s economy, faces a complex interplay of challenges and opportunities. Global market fluctuations, evolving consumer preferences, and environmental concerns all contribute to a dynamic landscape requiring adaptability and innovation. Sustainability initiatives and technological advancements are crucial for navigating these complexities and securing the industry’s long-term viability.

Major Challenges

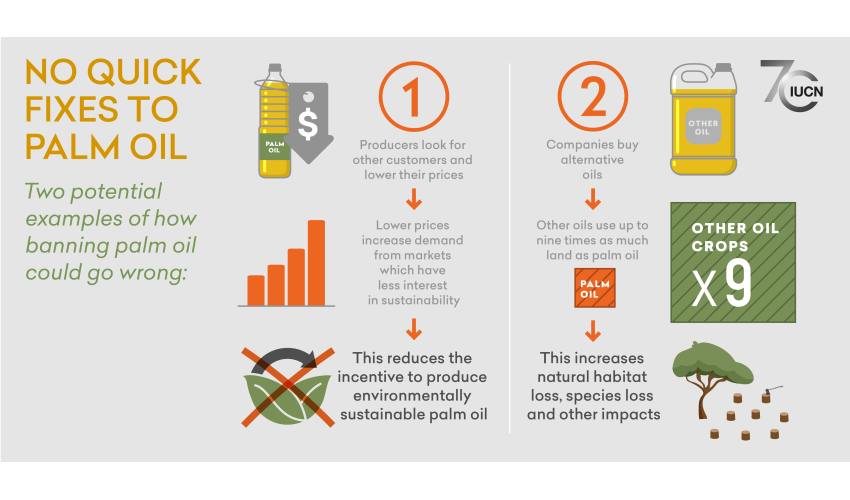

The palm oil industry confronts several significant hurdles. Competition from alternative oils, particularly from sustainable sources, is intensifying. Price volatility, influenced by global supply and demand dynamics, poses a considerable risk to producers. Labor costs, while fluctuating, continue to be a concern. Moreover, the industry faces scrutiny over its environmental impact, including deforestation and biodiversity loss. These challenges necessitate a multifaceted approach to ensure the industry’s long-term success and social responsibility.

Potential Opportunities for Innovation

The industry can leverage technological advancements to improve efficiency and sustainability. Precision agriculture techniques, optimized fertilization, and water management can enhance yields and reduce resource consumption. Biofuel production offers a potential avenue for value addition, transforming palm oil into a more versatile energy source. Moreover, new processing technologies can extract higher-quality oils and byproducts, creating avenues for diversified revenue streams. Research into sustainable palm oil cultivation practices, including agroforestry integration, is crucial.

Impact of Climate Change

Climate change presents a significant threat to palm oil production. Extreme weather events, including droughts and floods, can disrupt yields and negatively impact production cycles. Changing temperature patterns can also affect the optimal growing conditions for palm trees, potentially reducing yields and impacting the overall output. Adapting to climate change through drought-resistant varieties and improved water management techniques is critical for the future of palm oil production.

Importance of Research and Development

Investment in research and development is paramount for addressing the challenges and capitalizing on the opportunities within the palm oil industry. Research into genetically modified palm varieties with improved yield, disease resistance, and drought tolerance can enhance production efficiency. Studies on sustainable cultivation methods, such as agroforestry and integrated pest management, can minimize the environmental impact of palm oil production. Research into the potential of palm oil as a biofuel and alternative feedstock can generate new market opportunities.

Technological Advancements in Palm Oil Processing

Technological advancements in palm oil processing are transforming the industry. These innovations aim to enhance efficiency, sustainability, and profitability.

| Technology | Description | Impact |

|---|---|---|

| High-pressure extraction | Advanced extraction methods that utilize high pressure to separate oils from the fruit pulp, increasing efficiency and reducing waste. | Improved oil yield and reduced environmental impact through minimized solvent use. |

| Enzyme-based processing | Utilizing enzymes to accelerate the separation and purification of palm oil components, enhancing quality and minimizing processing time. | Higher-quality palm oil products, improved processing efficiency, and potential for cost savings. |

| Advanced fractionation techniques | Sophisticated separation methods that refine the different components of palm oil into various products, like stearin, olein, and palmitin. | Production of specialized palm oil products for diverse applications and enhanced value creation. |

Social and Economic Impacts

Palm oil’s pervasive presence in Malaysian society extends far beyond the agricultural sector. Its production, processing, and consumption deeply intertwine with the country’s economic fabric, influencing communities and livelihoods across diverse demographics. Understanding these impacts is crucial to evaluating the sustainability of the industry and its long-term benefits for Malaysia.

Social Impact on Malaysian Communities

The palm oil industry’s social footprint is complex, encompassing both positive and negative aspects. While providing employment opportunities, particularly in rural areas, it also raises concerns about land acquisition, displacement of indigenous communities, and environmental consequences. The social impact varies regionally and depends on the specific policies and practices implemented by individual estates and the government. Addressing these challenges is vital for ensuring equitable development and minimizing potential social unrest.

Economic Benefits to Malaysia

Palm oil is a significant contributor to Malaysia’s economy, generating substantial revenue and fostering numerous associated industries. It serves as a vital export commodity, bolstering foreign exchange earnings and providing substantial tax revenue for the government. The sector’s impact extends beyond direct employment, supporting downstream industries like food processing, cosmetics, and biofuels, thus stimulating economic growth across diverse sectors.

Employment Opportunities in the Palm Oil Industry

The palm oil industry provides a substantial number of jobs, from farm labor to processing and marketing. This employment extends to various skill levels, offering opportunities for both unskilled and skilled workers. The industry’s capacity to generate employment, especially in rural areas, often plays a crucial role in poverty reduction and community development. However, the nature of employment within the sector requires careful consideration, particularly in light of potential labor practices and conditions.

Potential for Job Creation and Economic Growth

The potential for job creation and economic growth associated with palm oil hinges on responsible development and investment. The industry’s expansion can generate jobs in related sectors, like agricultural machinery, logistics, and research and development. Sustainable practices and innovation can further enhance the sector’s economic impact by attracting foreign investment and creating higher-value jobs. The industry’s capacity to support technological advancements and innovation can further enhance its economic contribution.

Economic Contributions of the Palm Oil Sector to Malaysia

The palm oil sector’s contributions to Malaysia’s economy are significant and multifaceted. These contributions extend beyond direct revenues and encompass the broader economic ecosystem fostered by the industry. The following table summarizes some key economic contributions:

| Category | Description | Estimated Contribution (Illustrative) |

|---|---|---|

| Direct Revenue Generation | Revenue generated from palm oil exports and domestic sales | USD X billion (estimate) |

| Tax Revenue | Tax contributions from the industry to the Malaysian government | USD Y million (estimate) |

| Employment | Number of jobs directly and indirectly supported by the palm oil industry | Z thousand (estimate) |

| Downstream Industries | Support for related industries (e.g., food processing, cosmetics) | USD P billion (estimate) |

Note: The values in the table are illustrative and should not be considered definitive. Actual figures can vary depending on the specific year and data source.

Malaysia’s palm oil industry, a significant global commodity, extends beyond culinary uses. Derived from the fruit of the oil palm, palm nut oil, increasingly recognized for its hair-care benefits, offers a natural alternative for moisturizing and conditioning. This versatile product, sourced from the same fruit as Malaysia’s renowned palm oil, is experiencing a surge in popularity, underscoring the diverse applications of this crucial agricultural commodity.

palm nut oil for hair This underscores the remarkable range of applications inherent within the Malaysian palm industry.

Future Outlook

The Malaysian palm oil industry faces a complex future, balancing the demands of a growing global market with the need for sustainable practices. Forecasting future trends requires careful consideration of shifting consumption patterns, emerging technologies, and environmental concerns. The industry’s ability to adapt and innovate will be crucial to its long-term success.

Future Demand and Supply Dynamics

Palm oil’s demand is projected to continue its upward trajectory driven by increasing global population and rising incomes in developing economies. The growing demand for processed foods, biodiesel, and various industrial applications will sustain this trend. However, supply-side dynamics are not as straightforward. Factors such as weather patterns, land availability, and labor costs will influence production volumes. Fluctuations in these variables can create price volatility and market uncertainty.

Potential for New Applications

The versatility of palm oil presents opportunities for novel applications beyond its traditional uses. Research into its potential in bio-based plastics, lubricants, and personal care products is ongoing. The development of these alternative applications can diversify the industry’s revenue streams and reduce reliance on traditional markets. For example, palm-based bioplastics are gaining traction as a sustainable alternative to petroleum-derived plastics.

Research and Development Activities

Extensive research and development efforts are underway to improve palm oil’s efficiency and sustainability. Scientists are exploring ways to optimize yields, enhance disease resistance in palm trees, and develop environmentally friendly cultivation methods. These advancements are crucial to meeting the growing demand while minimizing the environmental impact. Notable research includes genetic engineering studies aimed at enhancing productivity and disease resistance in palm oil plantations.

Biofuel Production Potential

Palm oil’s suitability as a biofuel feedstock is a significant area of focus. The high oil content and ease of processing make it a viable alternative to fossil fuels. However, environmental concerns regarding deforestation and land use change need careful consideration. Policy frameworks and incentives are crucial to encourage sustainable biofuel production from palm oil. For instance, some countries have implemented mandates for biofuel blends in transportation fuels.

Projected Growth of Palm Oil Production and Consumption

| Year | Projected Palm Oil Production (Million Metric Tons) | Projected Palm Oil Consumption (Million Metric Tons) |

|---|---|---|

| 2024 | 75 | 70 |

| 2025 | 78 | 75 |

| 2026 | 82 | 80 |

| 2027 | 85 | 85 |

| 2028 | 88 | 90 |

Note: Projections are based on current market trends and expert estimates. Actual figures may vary due to unforeseen circumstances.

Illustrative Examples (Images/Graphs): Malaysia Palm

Visual representations are crucial for understanding the complex dynamics of the Malaysian palm oil industry. They offer a concise and accessible way to grasp key trends, trade flows, and production processes. These illustrations, from global trade routes to production timelines, provide a powerful tool for investors and policymakers to analyze the industry’s current state and future potential.

Global Palm Oil Trade Routes Infographic

This infographic would visually map the major trade routes for palm oil globally. It would highlight the key exporting countries, including Malaysia, and the principal import destinations. Different colored lines or arrows could represent various trade volumes and routes, providing a dynamic representation of the industry’s international reach. The infographic should clearly identify key shipping ports and major consumer markets. For instance, the route from Malaysian ports to Chinese ports would be emphasized with a thicker line to represent the high volume of trade. An interactive element, like clickable regions on the map, could allow viewers to delve deeper into specific trade relationships.

Malaysian Palm Oil Production Trends (Bar Graph)

A bar graph illustrating Malaysian palm oil production over the past decade would clearly showcase the production trends. The graph would display yearly production figures for each year, allowing for a direct comparison of output. The bars could be color-coded to visually represent significant growth periods or periods of stagnation. A trendline could be overlaid on the graph to illustrate the overall growth pattern. For example, the graph might show a steady increase in production from 2013 to 2020, with a notable dip in 2016 due to weather-related disruptions.

Distribution of Malaysian Palm Oil Exports (Pie Chart)

A pie chart representing the distribution of Malaysian palm oil exports would visually demonstrate the proportion of exports directed towards different countries or regions. Each segment of the pie chart would represent a specific destination market. The size of each segment would correspond to the percentage of exports shipped to that region. For example, China might represent the largest segment, followed by India, Indonesia, and other major importers. A legend would clarify the specific regions or countries represented by each segment.

Palm Oil Refining Process (Flowchart)

A flowchart detailing the palm oil refining process would clearly illustrate the steps involved. The flowchart would begin with the arrival of raw palm fruit and end with the packaged refined oil. Each step in the process, such as fruit processing, crushing, extraction, bleaching, and deodorization, would be represented by a box or symbol in the flowchart. The flow of the product through each step would be clearly marked with arrows. The flowchart would provide a detailed breakdown of the steps involved in the refining process, including potential chemical treatments and their roles.

Stages of Palm Oil Production

- Fresh Fruit Bunch (FFB) Harvesting: This initial stage involves the collection of fresh fruit bunches from the palm trees. Modern harvesting methods, like mechanical harvesters, are employed to maximize efficiency. The efficiency of harvesting impacts the cost of production, impacting the final price of the product.

- Fruit Processing: The FFBs are then processed to extract the fruit pulp. This typically involves separating the fruit from the bunches and extracting the palm fruit pulp. This process may involve mechanical separation techniques, influencing the quality of the final product.

- Oil Extraction: The extracted pulp is further processed to separate the oil from the solid components. This often involves pressing or chemical extraction methods. The choice of method impacts the yield and quality of the extracted oil.

- Oil Refining: This stage involves refining the extracted crude palm oil to meet specific quality standards. Refining procedures typically include processes such as bleaching, deodorization, and fractionation. The refining process is crucial in ensuring the oil’s suitability for various applications.

- Packaging and Distribution: The refined palm oil is packaged and distributed to various consumers and industries. This final stage involves packaging the oil for sale, transportation, and storage.