How is palm oil made? This intricate process, vital to global food and industry, involves a series of steps from cultivating the fruit to refining the final product. Understanding the production lifecycle reveals the complexities and challenges surrounding this widely used commodity, including environmental and social implications.

From the initial planting of palm trees in specific geographical regions to the intricate harvesting and processing techniques, the production of palm oil is a multi-stage operation. Different types of palm oil, each with distinct properties and applications, require varying levels of processing. This article explores the entire process, from fruit ripening to final product.

Introduction to Palm Oil Production

Palm oil, a ubiquitous vegetable oil, plays a crucial role in the global food and industrial sectors. Its widespread use in everything from processed foods to cosmetics and biofuels underscores its economic significance. The crop’s dominance in the global vegetable oil market is a result of its high yield and relatively low production costs. Understanding the intricacies of palm oil production is vital to comprehending its impact on the environment and global trade.

The production of palm oil involves a complex interplay of factors, from the cultivation of the oil palm tree to the refining and processing of the extracted fruit. Different varieties of palm oil are used in diverse applications, reflecting the versatility of this crucial agricultural commodity.

Different Types of Palm Oil

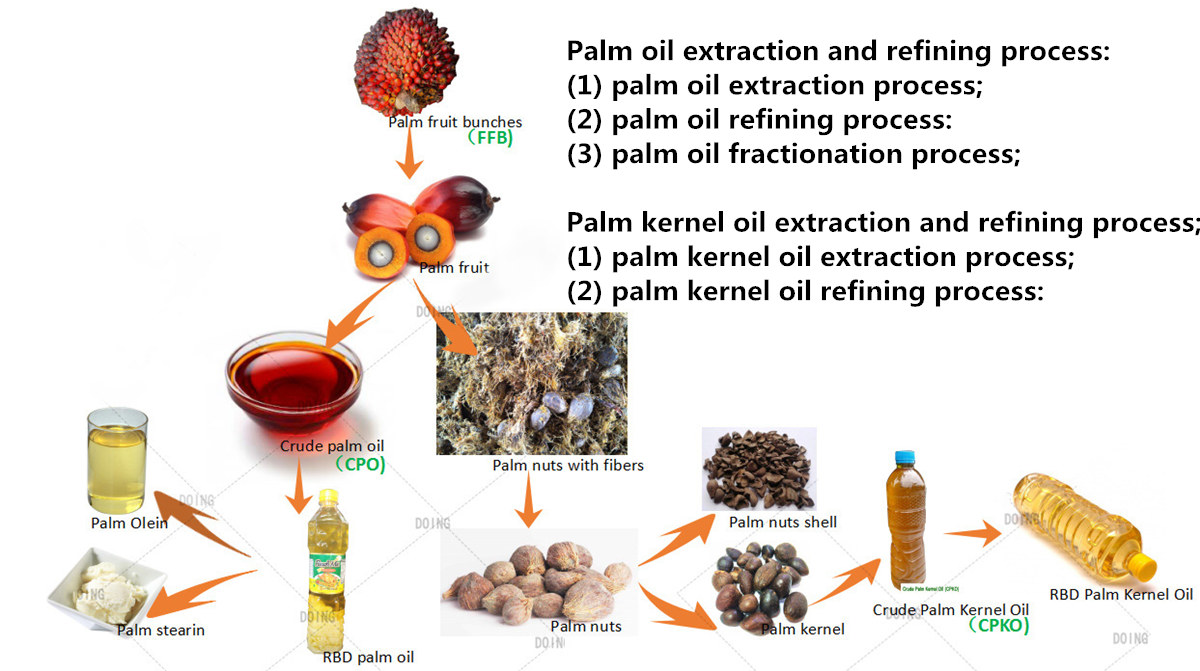

Palm oil is categorized into two primary types: fresh fruit bunch (FFB) palm oil and refined, bleached, and deodorized (RBD) palm oil. FFB oil is extracted directly from the fresh fruit bunches, while RBD oil undergoes a refining process to remove impurities and improve its quality and stability. This refinement significantly alters the oil’s properties and makes it suitable for various applications.

Historical Context of Palm Oil Cultivation

The cultivation of oil palms has a long history, originating in West Africa. Early uses focused primarily on local consumption, but the global demand for vegetable oils spurred significant expansion in the 20th century. The modern industrial scale of palm oil production has been a key driver of economic growth in several countries, especially in Southeast Asia.

Geographical Areas of Palm Oil Production

The majority of the world’s palm oil is produced in Southeast Asia, primarily in Indonesia and Malaysia. These countries possess favorable climates and fertile land suitable for extensive palm oil plantations. Other regions, like parts of Africa and South America, also contribute to global palm oil production, albeit on a smaller scale.

Comparison of Palm Oil Types

| Type | Uses | Properties |

|---|---|---|

| Fresh Fruit Bunch (FFB) Palm Oil | Direct consumption, some food products (e.g., cooking oil), certain industrial applications. | Naturally occurring, typically lower in processing. Can vary in color and consistency based on the stage of the fruit. |

| Refined, Bleached, and Deodorized (RBD) Palm Oil | Wide range of applications, including processed foods, cosmetics, biofuels, and industrial products. | Higher quality, consistent properties, and longer shelf life compared to FFB oil. Color and odor are removed during the refining process. |

The Palm Fruit and Harvesting

The production of palm oil hinges on the efficient and sustainable harvesting of the fruit from the oil palm tree. Understanding the intricacies of fruit ripening and the various harvesting methods employed is crucial for optimizing yield and minimizing environmental impact. Different techniques exist, each with varying levels of labor intensity and environmental consequences.

The oil palm fruit undergoes a complex ripening process before it’s ready for harvest. This intricate biological process influences the quality and yield of the extracted oil. Various factors, including weather patterns and soil conditions, can affect the speed and uniformity of this ripening. Careful monitoring of these factors is essential for maximizing the harvest.

Palm Fruit Ripening and Maturation

The oil palm fruit progresses through distinct stages of ripening, each characterized by changes in color, size, and physical properties. The fruit typically begins as a green, hard fruit, gradually transitioning to a yellowish-orange or reddish color as it matures. This color change signifies the accumulation of oil within the fruit, indicating its readiness for harvest. The process of maturation is influenced by environmental factors such as temperature and rainfall. Variations in these factors can lead to uneven ripening, requiring careful monitoring and potentially adjustments to harvest schedules.

Harvesting Methods

Several methods are employed for harvesting palm fruit, each with its own set of advantages and disadvantages. The most common methods include manual harvesting, using equipment like hand-held knives or clippers, and mechanical harvesting, employing specialized machinery. Manual harvesting, while labor-intensive, can often target specific bunches of fruit, minimizing waste. Mechanical harvesting, on the other hand, is more efficient in terms of time and labor, but may lead to greater damage to the trees and potentially higher environmental impacts.

Tools and Equipment

The tools and equipment used in palm fruit harvesting vary depending on the chosen method. Manual harvesting relies on tools such as hand-held knives, clippers, and baskets for collecting the fruit. Mechanical harvesting utilizes specialized harvesters, often incorporating a combination of mechanical arms, conveyors, and collection systems. The design and effectiveness of these tools significantly influence the efficiency and safety of the harvesting process.

Comparison of Harvesting Techniques and Environmental Impact

Manual harvesting, while less efficient, often has a lower environmental footprint than mechanical harvesting. Manual methods generally result in less damage to the trees and surrounding vegetation. However, the labor-intensive nature of manual harvesting can impact labor costs. Mechanical harvesting, although more efficient, may lead to greater damage to the trees and surrounding ecosystems, potentially impacting soil erosion and biodiversity. Careful maintenance and operation of the machinery are crucial to minimize these negative effects.

Stages of Palm Fruit Harvesting

| Stage | Description |

|---|---|

| Fruit Ripening | The fruit progresses through stages of color change, size increase, and oil accumulation. Careful observation and monitoring are crucial. |

| Harvesting Preparation | Assessment of ripeness, selection of the harvesting method (manual or mechanical), and preparation of the harvesting equipment. |

| Fruit Collection | Direct collection of the ripe fruit using hand tools or machinery. Proper handling to minimize damage is essential. |

| Post-Harvest Handling | Transporting the harvested fruit to processing facilities, and initial sorting and cleaning procedures. |

Extraction of Palm Oil: How Is Palm Oil Made

The journey from harvested fruit to refined palm oil involves a crucial stage: extraction. This process, which transforms the fleshy fruit into a usable commodity, varies significantly depending on the scale of operation, from smallholder farms to large-scale industrial settings. Understanding these extraction methods is key to comprehending the economics and environmental impact of palm oil production.

Mechanical Extraction Methods

Mechanical methods, primarily used in both small-scale and large-scale operations, leverage physical forces to separate the oil from the fruit pulp. These methods are generally more cost-effective for smaller-scale operations.

- Traditional Methods: These methods frequently involve manual processes, such as crushing the fruit with heavy stones or using rudimentary presses. The resulting oil often requires further processing to achieve desired quality standards. This approach, though labor-intensive, is commonly employed in regions with limited access to modern equipment.

- Modern Mechanical Methods: Larger-scale operations utilize sophisticated machinery. These include milling machines and hydraulic presses. Modern methods generally improve efficiency, though they may still necessitate pre-treatment of the fruit to enhance oil extraction.

Chemical Extraction Methods

Chemical extraction, less common than mechanical methods in palm oil production, employs solvents to dissolve the oil from the fruit pulp. While capable of high extraction rates, the use of solvents raises concerns about environmental impact and worker safety.

- Solvent Extraction: Solvents, such as hexane, are employed to extract the oil. This method often results in a higher oil yield but also introduces potential environmental hazards from solvent disposal and worker exposure. The cost of implementing and maintaining the required safety precautions is also a factor.

Comparison of Extraction Methods

The choice of extraction method depends on various factors, including the size of the operation, the available technology, and the desired quality of the final product. The efficiency and cost-effectiveness of different methods vary considerably.

| Extraction Method | Advantages | Disadvantages |

|---|---|---|

| Traditional Mechanical Methods | Lower capital investment, potentially lower labor costs in some contexts, lower environmental impact in some instances depending on scale and implementation. | Lower efficiency, lower oil yield, quality of the extracted oil can be inconsistent, labor-intensive. |

| Modern Mechanical Methods | Higher efficiency, higher oil yield, potential for better quality control, more consistent product. | Higher capital investment, potential for higher labor costs, potential environmental impact from machinery operation. |

| Solvent Extraction | Highest oil yield, potentially faster extraction. | Environmental concerns due to solvent usage, health hazards from solvent exposure, higher processing costs, strict safety regulations required. |

Refining and Processing

Palm oil, after extraction, undergoes a crucial refining process to achieve the desired quality and remove impurities. This refining stage is essential for ensuring the oil’s suitability for various applications, from food products to biofuels. The process involves meticulous steps, including the removal of free fatty acids, pigments, and other contaminants. The refined product’s quality is critical for consumer safety and product consistency.

Refining Processes

The refining process for palm oil is a multi-stage procedure designed to enhance the oil’s quality and stability. This involves several key steps, including degumming, bleaching, and deodorization. Each step targets specific impurities to produce a consistent and safe product.

- Degumming: This initial stage removes gums and mucilaginous substances, which are natural components of the fruit, that can interfere with the oil’s properties. The process typically uses chemicals or enzymes to precipitate and separate these impurities. This is a crucial step to prevent issues during subsequent processing stages and ensure a clean, smooth oil.

- Neutralization: This stage neutralizes free fatty acids, often present in crude palm oil, that can contribute to rancidity and affect the oil’s stability. The neutralization process uses alkali solutions, which react with the free fatty acids, rendering them harmless. Proper neutralization is vital to extend the shelf life of the refined oil and maintain its quality.

- Bleaching: This process removes color pigments and other impurities that affect the appearance and flavor of the oil. Activated earth, like clays, is commonly used to absorb these impurities. Bleaching improves the aesthetic appeal of the product, making it suitable for a variety of food applications.

- Deodorization: This critical stage removes undesirable odors and volatile compounds that can negatively affect the taste and aroma of the oil. The oil is heated and subjected to vacuum conditions, which evaporate volatile compounds and improve the overall quality of the refined product. This process is vital for the sensory appeal of the final product.

Grades of Palm Oil

Different grades of palm oil cater to specific needs and applications. These variations are based on factors like the refining process, color, and the level of impurities present.

- Crude Palm Oil (CPO): This is the unrefined oil, which retains the natural characteristics of the fruit. It is often used in industrial applications and in the production of biofuels.

- RBD Palm Oil: Refined, bleached, and deodorized palm oil is a widely used grade. Its refined nature makes it suitable for various food applications. This grade is typically the preferred choice for food processing, with specific standards and certifications.

- Fractionated Palm Oil: This is a further refined form of palm oil that separates the oil into different components based on their melting points. This separation allows for tailored products for specific applications.

Quality Control, How is palm oil made

Ensuring consistent quality in palm oil processing is paramount. This involves rigorous testing and monitoring at every stage to ensure the final product meets specifications. Quality control procedures typically include checking for contaminants, verifying chemical compositions, and assessing the physical properties of the oil.

Palm Oil Refining Stages

| Stage | Process | Outcome |

|---|---|---|

| Degumming | Removal of gums and mucilage | Crude palm oil with reduced impurities |

| Neutralization | Neutralization of free fatty acids | Oil with improved stability and reduced rancidity |

| Bleaching | Removal of color pigments and impurities | Oil with improved color and clarity |

| Deodorization | Removal of volatile compounds and odors | Oil with enhanced aroma and flavor |

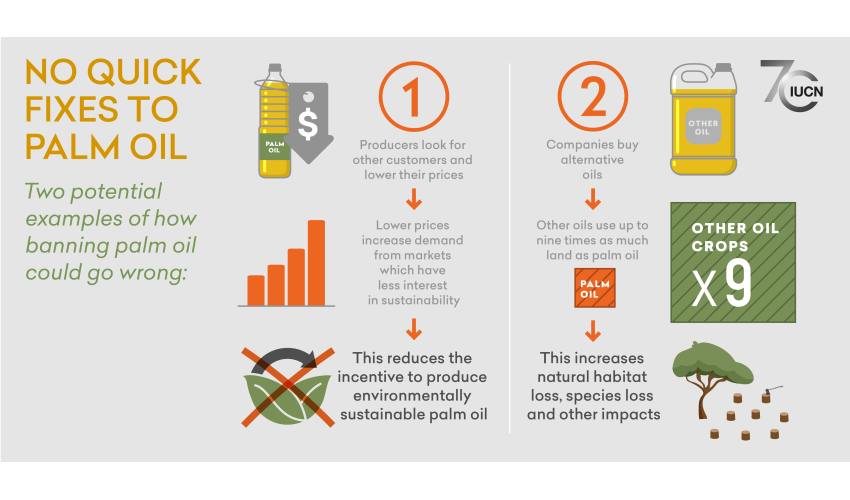

Environmental and Social Impacts

Palm oil’s ubiquitous presence in consumer products masks a complex web of environmental and social challenges. While offering a readily available and cost-effective source of fat, its production often comes at a steep price for biodiversity, local communities, and the planet’s health. This section delves into the ecological and societal consequences of palm oil cultivation, highlighting the ongoing efforts to achieve sustainable practices.

Environmental Concerns

Deforestation and habitat loss are primary environmental concerns associated with palm oil production. Vast swathes of tropical rainforests, crucial ecosystems teeming with unique species and vital for carbon sequestration, are cleared to make way for oil palm plantations. This conversion contributes significantly to biodiversity loss and climate change. Furthermore, the use of pesticides and fertilizers in intensive palm oil operations can pollute water sources, harming aquatic life and potentially impacting human health. The release of greenhouse gases from deforestation and land use changes also contributes to global warming.

Social Impacts

Palm oil production frequently displaces indigenous communities and local farmers from their ancestral lands. The loss of livelihoods and traditional ways of life can have severe social consequences. Furthermore, labor practices in some palm oil operations have been criticized for exploitative conditions, including low wages, unsafe working environments, and restrictions on worker mobility. The resulting social unrest and inequality often complicate the efforts to develop sustainable practices.

Sustainability Efforts

Growing awareness of the environmental and social impacts of palm oil production has spurred efforts toward more sustainable practices. These efforts encompass a range of strategies, including the promotion of sustainable land management, responsible sourcing, and fair labor practices. Crucially, these initiatives aim to minimize the negative externalities of palm oil production and contribute to a more equitable and environmentally conscious industry.

Sustainable Palm Oil Certifications

Several certifications and standards have emerged to promote sustainable palm oil production. These certifications typically evaluate plantations and supply chains against criteria focused on environmental protection, social equity, and responsible management. Examples include the Roundtable on Sustainable Palm Oil (RSPO), the Malaysian Sustainable Palm Oil (MSPO) certification, and others. These certifications offer a framework for producers to demonstrate their commitment to sustainability and provide consumers with a means to identify and support responsible palm oil products.

Summary Table: Environmental and Social Impacts of Palm Oil Production Methods

| Production Method | Environmental Impacts | Social Impacts |

|---|---|---|

| Conventional/Unsustainable | High deforestation rates, biodiversity loss, water pollution, greenhouse gas emissions. | Displacement of indigenous communities, poor labor practices, low wages, unsafe working conditions. |

| Certified Sustainable (e.g., RSPO) | Reduced deforestation, improved biodiversity conservation, minimized pollution, lower greenhouse gas emissions. | Improved labor standards, fair wages, safe working conditions, greater community involvement. |

Future Trends in Palm Oil Production

The palm oil industry, a crucial global commodity, faces a complex interplay of technological advancements, environmental concerns, and evolving consumer demands. The future of palm oil production hinges on the industry’s ability to adapt to these pressures, balancing profitability with sustainability. This necessitates a shift towards more environmentally responsible practices and the integration of innovative technologies.

Emerging Trends in Production and Processing

The palm oil industry is witnessing a growing emphasis on sustainable practices, including the development of genetically modified palm varieties with higher oil yields and reduced environmental impact. These advancements, coupled with precision agriculture techniques, promise to enhance efficiency and minimize land use. Moreover, innovations in processing technologies are aimed at improving oil extraction rates and minimizing waste generation.

Advancements in Technology and Innovation

Precision agriculture techniques, leveraging data analytics and sensor technologies, are revolutionizing palm oil cultivation. These tools enable farmers to optimize resource allocation, monitor crop health, and minimize pesticide use. Furthermore, advancements in biotechnology are yielding genetically modified palm varieties with enhanced oil content and disease resistance. These innovations promise increased yields with reduced environmental footprints.

Potential Impact of Climate Change

Climate change poses a significant threat to palm oil production. Rising temperatures and altered rainfall patterns can impact yields and potentially increase the susceptibility of palm trees to pests and diseases. Research is focusing on developing climate-resilient palm varieties and adapting cultivation practices to mitigate these risks. The industry is also exploring strategies to reduce the carbon footprint of palm oil production, such as carbon sequestration techniques.

Research and Development in Sustainable Palm Oil Production

Several initiatives are underway to promote sustainable palm oil production. These include the development of certified sustainable palm oil schemes, the use of more environmentally friendly fertilizers, and the exploration of alternative extraction methods that minimize water usage. Researchers are also investigating the potential of integrated farming systems to enhance biodiversity and ecosystem services. One notable example is the development of palm oil plantations that incorporate reforestation efforts, thereby restoring degraded landscapes and minimizing deforestation.

Table Summarizing Potential Future Trends

| Trend | Technological Aspect | Environmental Aspect |

|---|---|---|

| Precision Agriculture | Data analytics, sensor technologies, optimized resource allocation | Reduced pesticide use, minimized land use |

| Biotechnology | Genetically modified varieties with enhanced oil content and disease resistance | Increased yields, reduced environmental impact |

| Climate-Resilient Varieties | Development of palm varieties adapted to changing climate conditions | Enhanced yield stability, reduced vulnerability to pests and diseases |

| Sustainable Certification | Standardized criteria for sustainable palm oil production | Reduced deforestation, enhanced biodiversity |

| Integrated Farming Systems | Combining palm oil plantations with reforestation efforts | Improved ecosystem services, carbon sequestration |

Palm oil production, a process involving extracting the oil from the fruit of the oil palm tree, often involves refining and bleaching stages. While the extraction method significantly impacts the final product, exploring the potential health benefits of palm kernel oil for skin and hair is also worthwhile. Discover the Health Benefits of Palm Kernel Oil for Your Skin and Hair Understanding the nuances of processing and extraction is crucial for evaluating the overall impact of palm oil on the market and in various applications.

This intricate process ultimately dictates the quality and usability of the oil, influencing its downstream applications and potential market value.