How to make soap without palm oil is a growing concern for environmentally conscious consumers. Palm oil production often comes with deforestation and ethical issues. This guide explores sustainable alternatives and detailed recipes for creating beautiful, palm-free soaps, from sourcing sustainable ingredients to crafting unique variations.

The guide covers various soap-making methods, including cold process, hot process, and melt and pour, each with its own advantages and disadvantages. Detailed recipes, using coconut oil, olive oil, and shea butter, are provided, along with insights into essential oils and additives, and troubleshooting common problems. The guide also emphasizes the importance of sustainable sourcing and the environmental and ethical implications of palm oil.

Introduction to Palm Oil-Free Soap Making

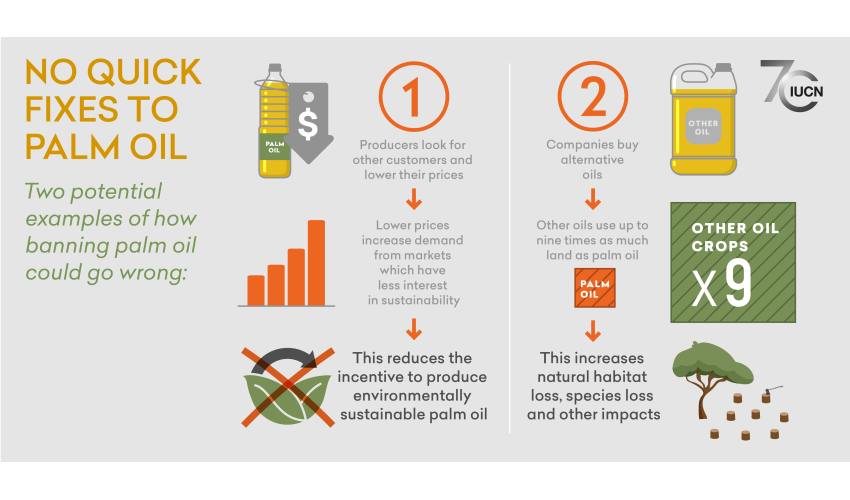

Palm oil, a ubiquitous ingredient in many consumer products, including soap, faces increasing scrutiny for its environmental and ethical implications. Deforestation driven by palm oil plantations contributes to biodiversity loss and climate change. Furthermore, labor practices in some palm oil supply chains raise concerns about worker exploitation. Consumers are increasingly seeking alternatives to palm oil, driving demand for sustainable and ethically sourced ingredients in personal care products.

Making soap without palm oil presents a compelling alternative, aligning with growing consumer demand for eco-conscious products. This approach not only reduces the environmental footprint but also supports ethical sourcing, promoting a more responsible and sustainable production process. Palm oil-free soap making offers a diverse range of methods, allowing for customized formulations and tailored results.

Environmental and Ethical Concerns of Palm Oil in Soap

Palm oil’s cultivation often involves significant deforestation and habitat destruction, contributing to biodiversity loss and greenhouse gas emissions. The large-scale production of palm oil can also negatively impact local communities, displacing indigenous populations and potentially leading to human rights abuses. These concerns underscore the need for alternatives and highlight the importance of sustainable sourcing in personal care products.

Benefits of Palm Oil-Free Soap Making

Palm oil-free soap production promotes environmental sustainability by reducing the reliance on palm oil. This approach contributes to the conservation of natural habitats and reduces the environmental impact associated with palm oil cultivation. Further, it supports ethical sourcing, promoting fair labor practices and ensuring a more responsible supply chain.

Different Types of Palm Oil-Free Soap Making Methods

Several methods exist for creating palm oil-free soaps, each with its unique advantages and disadvantages. Cold process soap making, a popular choice, involves combining oils and lye in a controlled environment, allowing the mixture to solidify into a bar of soap. Melt and pour soap making involves melting pre-made soap bases and adding fragrances, colors, and other ingredients. This method offers greater flexibility in terms of customization and is easier for beginners. Another approach, the hot process method, involves heating the oils and lye to a high temperature, followed by cooling and solidification, often resulting in a more refined and consistent product. Each method offers unique characteristics in terms of cost, effort, and the final product’s properties.

Comparison of Palm Oil-Based and Palm Oil-Free Soaps

| Characteristic | Palm Oil-Based Soap | Palm Oil-Free Soap |

|---|---|---|

| Ingredients | Often includes palm oil, offering relatively low production costs. | Employs alternative oils such as olive oil, coconut oil, and shea butter, which may increase production costs. |

| Environmental Impact | Can contribute to deforestation and habitat loss. Potentially higher carbon footprint. | Reduces environmental impact by avoiding palm oil cultivation and deforestation. Lower carbon footprint. |

| Ethical Considerations | Potentially linked to labor exploitation in some supply chains. | Supports ethical sourcing, often using locally sourced ingredients and fair labor practices. |

| Benefits | Generally inexpensive to produce. | Supports sustainable and ethical production, promoting responsible consumption. |

| Scent and Texture | May have a wide variety of scents and textures depending on the oils used. | Can have varied scents and textures based on the chosen ingredients. |

Sourcing Sustainable Alternatives

The quest for palm oil-free soap necessitates a careful evaluation of sustainable alternatives. Replacing palm oil requires a thorough understanding of the properties of various plant-based oils, and their impact on the final product. This section explores a range of sustainable options and their suitability for soap making.

Sustainable sourcing isn’t just about choosing an oil; it’s about the entire supply chain. Traceability and ethical production practices are crucial. Farmers and producers committed to sustainable farming practices are key to this effort. These practices often include responsible land management, water conservation, and fair labor practices.

Sustainable Plant-Based Oils

A diverse array of plant-based oils can effectively replace palm oil in soap making. These oils offer varying properties that influence the final soap’s characteristics, from lather to hardness. Understanding these differences is crucial for achieving desired results.

- Coconut Oil: Known for its creamy lather and moisturizing properties, coconut oil is a popular choice. Its high saturated fat content contributes to a hard, firm soap. However, the strong scent can be a consideration for some consumers.

- Olive Oil: A classic ingredient in soap making, olive oil provides a luxurious lather and excellent moisturizing qualities. Its relatively high content of unsaturated fats results in a softer, less hard soap compared to coconut oil. The mild scent is generally well-received.

- Shea Butter: A rich, emollient oil, shea butter adds a luxurious feel to soap. It provides excellent moisturizing properties and contributes to a smooth, creamy texture. Its higher price point compared to other oils might be a consideration.

- Palm Kernel Oil: Although derived from the same palm tree as palm oil, palm kernel oil is a distinct oil with different properties. It often creates a good lather and hardness, but it’s crucial to differentiate it from palm oil due to environmental concerns associated with palm oil cultivation.

- Castor Oil: A unique oil, castor oil contributes to the hardness and consistency of soap. It has a high viscosity and can enhance the stability of the soap mix, although its lather properties are often less desirable than other options.

Comparative Analysis of Oils

The table below summarizes the suitability of various plant-based oils for soap making, highlighting their pros and cons regarding lather, hardness, and other key characteristics.

| Oil | Lather | Hardness | Moisturizing | Scent | Sustainability Concerns | Pros | Cons |

|---|---|---|---|---|---|---|---|

| Coconut Oil | Creamy, abundant | Hard | High | Strong | Minimal, if sourced sustainably | Excellent lather, good moisturizing | Strong scent, may be less suitable for sensitive skin |

| Olive Oil | Rich, luxurious | Soft | High | Mild | Minimal, if sourced sustainably | Excellent moisturizing, mild scent | May result in softer soap |

| Shea Butter | Moderate | Moderate | Very high | Mild | Minimal, if sourced sustainably | Excellent moisturizing, luxurious feel | Higher cost, may affect lather |

| Palm Kernel Oil | Good | Moderate | Moderate | Mild | Potential for deforestation issues, if not sustainably sourced | Good balance of lather and hardness | Sustainability concerns if not carefully sourced |

| Castor Oil | Limited | Hard | Moderate | Mild | Minimal, if sourced sustainably | Good for consistency, hardness | Less desirable lather |

Soap Making Recipes (Palm Oil-Free)

Transitioning to palm oil-free soap making requires understanding the diverse range of sustainable alternatives. This section provides practical recipes using common and readily available ingredients, focusing on creating high-quality, effective, and environmentally conscious soap.

The recipes below offer flexibility in ingredient choices, allowing adjustments based on personal preferences and desired soap characteristics. Key factors like desired lather, hardness, and scent can be customized by altering ingredient ratios.

Coconut Oil-Based Soap Recipe

This recipe emphasizes the moisturizing properties of coconut oil, creating a creamy lather.

- Ingredients:

- 60% Coconut Oil

- 20% Olive Oil

- 10% Shea Butter

- 10% Water

- Essential Oils (optional)

- Lye Solution (calculated based on total oil weight)

- Procedure:

- Accurately measure and combine all oils in a heat-resistant container.

- Heat the mixture gently in a double boiler until the oils are fully melted and homogenous.

- Carefully calculate the lye solution using a reliable lye calculator, ensuring accurate measurements.

- Slowly pour the lye solution into the oil mixture, stirring constantly and ensuring complete mixing.

- Allow the soap to cure for a minimum of four weeks in a mold, or pour into a mold.

- Remove the soap from the mold and allow it to cure further, typically for several weeks, in a well-ventilated area.

- Once the soap has cured, slice it into bars and allow it to dry completely.

Olive Oil and Shea Butter Soap Recipe, How to make soap without palm oil

This recipe emphasizes a balance between moisturizing and cleansing properties, suitable for various skin types.

- Ingredients:

- 50% Olive Oil

- 30% Shea Butter

- 10% Coconut Oil

- 10% Water

- Essential Oils (optional)

- Lye Solution (calculated based on total oil weight)

- Procedure:

- Melt the oils together using a double boiler.

- Calculate the lye solution using a lye calculator and add it to the oil mixture, stirring constantly.

- Pour the mixture into a mold.

- Allow the soap to cure for a minimum of four weeks.

- Slice the soap into bars and allow to dry completely.

Castor Oil and Palm Kernel Oil Soap Recipe

This recipe demonstrates using sustainable alternatives to create a soap with a unique texture and properties.

- Ingredients:

- 40% Castor Oil

- 40% Palm Kernel Oil

- 10% Coconut Oil

- 10% Water

- Essential Oils (optional)

- Lye Solution (calculated based on total oil weight)

- Procedure:

- Combine all oils in a heat-resistant container.

- Heat the mixture gently in a double boiler until the oils are fully melted.

- Calculate the lye solution and add it to the oil mixture, stirring continuously.

- Pour the mixture into a mold.

- Allow the soap to cure for a minimum of four weeks, or until desired hardness is reached.

- Slice the soap into bars and allow to dry completely.

Essential Oils and Additives

Enhancing the sensory and potentially therapeutic properties of palm oil-free soaps often involves the strategic use of essential oils and other additives. These additions can significantly impact the scent, texture, and perceived benefits of the final product, but careful consideration of their potential effects is crucial. Understanding the properties of different additives and their safe incorporation into the soap-making process is paramount.

The judicious selection and application of essential oils and other additives in palm oil-free soaps are vital to achieving the desired results while minimizing potential risks. These elements contribute to the unique characteristics of each bar, offering diverse scents and even purported therapeutic benefits. However, some additives may pose sensitivities or irritations for certain individuals, necessitating careful evaluation and ingredient selection.

Essential Oil Selection and Properties

Essential oils are aromatic compounds extracted from various plant parts, often possessing distinct scents and potentially therapeutic properties. Their use in soap making provides a range of olfactory experiences and, potentially, skin benefits. For example, tea tree oil is known for its antiseptic properties, while lavender oil is frequently associated with relaxation. Careful consideration of individual sensitivities is crucial.

- Citrus Essential Oils: Citrus oils like lemon, orange, and grapefruit are known for their invigorating scents and potential brightening effects. However, they can be photosensitizing, meaning they can increase the skin’s sensitivity to sunlight. Appropriate precautions are essential for users.

- Floral Essential Oils: Floral oils like rose, lavender, and chamomile offer calming and relaxing scents. They are generally considered safe for most skin types but may trigger allergic reactions in some individuals.

- Herbal Essential Oils: Herbal oils such as tea tree, peppermint, and eucalyptus often have antiseptic or stimulating properties. Tea tree oil, for instance, is frequently used for its antiseptic qualities, but caution is advised as excessive use can cause skin irritation.

Safe Incorporation of Additives

Proper incorporation of essential oils and other additives is vital for achieving desired effects and minimizing potential risks. Start with small quantities to assess individual tolerance levels. Diluting essential oils with carrier oils like jojoba or almond oil can lessen the risk of skin irritation and improve their efficacy. Moreover, careful attention to the specific instructions and guidelines provided by the chosen additive supplier is critical.

Additive Interactions and Potential Risks

Certain additives can interact with each other or with the soap’s base ingredients. This can lead to undesirable outcomes or even skin reactions. For instance, combining highly alkaline ingredients with certain essential oils can compromise the effectiveness or safety of the resulting soap.

| Essential Oil | Potential Effects on Skin |

|---|---|

| Tea Tree Oil | Antiseptic, potential for skin irritation in some individuals, especially with prolonged or concentrated use. |

| Lavender Oil | Calming, relaxing, generally safe for most skin types, but potential for allergic reactions in sensitive individuals. |

| Peppermint Oil | Stimulating, cooling, potential for skin irritation in some individuals, especially with direct application or concentrated use. |

| Lemon Oil | Invigorating, brightening, photosensitizing, caution needed for individuals prone to sun sensitivity. |

Soap Making Techniques

Crafting palm-oil-free soap involves a variety of techniques, each offering distinct advantages and disadvantages in terms of complexity, yield, and the final product’s characteristics. Understanding these methods allows soap makers to choose the approach best suited to their skill level, desired outcome, and available resources.

Different techniques offer varying degrees of control over the soap’s properties. Cold process, for example, allows for a more hands-on approach in controlling the saponification process, while melt and pour offers a quicker and easier method for those seeking a more straightforward process. The hot process, in contrast, enables fine-tuning of the chemical reaction. Ultimately, the best method hinges on individual preferences and the intended application of the soap.

Cold Process Soap Making

Cold process soap making is a popular choice for beginners and experienced soap makers alike. It involves combining oils, lye, and fragrance oils at room temperature, allowing the soap to cure in a mold for several weeks.

The process typically involves several steps:

- Weighing and measuring the oils and lye with precision. This ensures accurate ratios and optimal saponification.

- Mixing the lye solution with the oils in a controlled manner to prevent overheating.

- Pouring the mixture into molds and allowing the soap to cure for several weeks, ensuring complete saponification.

- After curing, the soap is removed from the molds, cut into bars, and allowed to dry further.

This method’s advantage lies in its relative simplicity and hands-on approach, allowing for creative customization with colors, fragrances, and additives. A disadvantage is the extended curing time, potentially requiring several weeks for complete saponification.

Hot Process Soap Making

Hot process soap making involves heating the oils and lye solution to a specific temperature before mixing, allowing for a faster and more controlled saponification process.

The steps involved include:

- Heating the oils in a separate container to a precise temperature.

- Preparing the lye solution separately, ensuring careful handling and proper safety precautions.

- Slowly pouring the hot lye solution into the hot oils, stirring continuously until the mixture reaches a desired consistency.

- Pouring the mixture into molds and allowing the soap to cure for several days, ensuring complete saponification.

This technique allows for a quicker saponification process compared to cold process, potentially yielding soap in a few days. However, careful temperature control and handling are critical to avoid accidents.

Melt and Pour Soap Making

Melt and pour soap making provides a straightforward and quick method for creating soap. It involves melting pre-made soap bases and adding colors, fragrances, and other desired additives.

The process usually involves:

- Melting the soap base in a double boiler or microwave, ensuring a consistent temperature to avoid scorching.

- Adding desired additives such as essential oils, colors, and other ingredients to the melted base.

- Pouring the mixture into molds and allowing it to cool and solidify.

This method’s primary advantage is its speed and ease, allowing for rapid creation of soap. However, the result is often less customizable than cold or hot process methods, as it relies on pre-made bases.

Comparison Table of Soap Making Methods

| Method | Process | Advantages | Disadvantages |

|---|---|---|---|

| Cold Process | Room temperature mixing, extended curing | Relatively simple, hands-on customization | Longer curing time |

| Hot Process | Heating oils and lye solution | Faster saponification, more control over process | Requires careful temperature control, potential for accidents |

| Melt and Pour | Melting pre-made base | Quickest method, easy customization with additives | Less control over ingredients, limited customization |

Soap Ingredients and Their Properties

Crafting palm-oil-free soap hinges on understanding the diverse roles of each ingredient and their interactions. Substituting palm oil necessitates careful selection of alternatives, ensuring the finished product maintains desirable qualities like lather, hardness, and moisturizing properties. This section delves into the specific functions of various components, emphasizing the importance of high-quality materials for a successful and sustainable soap-making venture.

Key Soap Ingredients and Their Roles

Understanding the functions of each ingredient is paramount to achieving the desired soap characteristics. Different oils, fats, and additives contribute unique properties, influencing the lather, hardness, and moisturizing qualities of the final product. The careful selection and proportioning of these ingredients are critical to success.

Oils and Fats: The Foundation of Palm-Oil-Free Soaps

Oils and fats are the primary building blocks of soap. Their chemical structure dictates the soap’s properties, including lather, hardness, and moisturizing attributes. High-quality oils and fats contribute to a superior product. Common palm-oil-free options include coconut oil, olive oil, castor oil, and shea butter. Coconut oil, for instance, produces a rich, creamy lather, while olive oil provides a mild and moisturizing effect.

Lye: The Essential Chemical Reactant

Sodium hydroxide, commonly known as lye, is the crucial chemical component that initiates the saponification process, converting oils and fats into soap. It’s a potent substance, demanding utmost caution during handling and mixing. Accurate measurement and controlled addition are critical to avoid hazardous reactions and ensure a successful outcome.

Additives: Enhancing the Soap’s Attributes

Additives enhance the soap’s aesthetic and functional properties. These include essential oils, herbs, clays, and colorants. Essential oils impart fragrance and potential therapeutic benefits, while herbs and clays can add color and texture.

Water: The Solvent and Carrier

Water acts as a solvent, dissolving the lye and facilitating the saponification reaction. The quantity of water used influences the consistency of the soap mixture. Precise measurement of water is essential to achieve the correct consistency and prevent potential issues during the saponification process.

Table of Soap Ingredients and Their Functions

| Ingredient Category | Ingredient Examples | Function | Impact on Final Product |

|---|---|---|---|

| Oils & Fats | Coconut Oil, Olive Oil, Castor Oil, Shea Butter | Provide the base for the soap, influencing lather, hardness, and moisturizing properties. | Determines the overall feel, texture, and cleansing ability of the soap. |

| Lye | Sodium Hydroxide | Initiates the saponification process, converting oils and fats into soap. | Essential for creating the soap, must be handled with extreme care. |

| Additives | Essential Oils, Herbs, Clays, Colorants | Enhance the aesthetic and functional properties of the soap, including fragrance, color, and texture. | Adds fragrance, color, and other desirable attributes. |

| Water | Distilled Water | Solvent for lye and facilitates saponification. | Influences the consistency and overall product quality. |

Troubleshooting and Common Issues

Crafting palm oil-free soap presents unique challenges, but understanding potential pitfalls and their solutions empowers soap makers to produce high-quality, consistent products. Troubleshooting effectively allows for a more rewarding and efficient soap-making journey. From unexpected texture issues to slow curing, meticulous attention to detail and problem-solving are key.

Troubleshooting Soap Hardening

Proper hardening is critical for a usable soap bar. Several factors influence this process, including the ratio of oils, the curing environment, and the soap’s base. Insufficient curing time, for example, can lead to a soft, pliable soap that fails to hold its shape. Conversely, rapid curing in a humid environment can cause the soap to crack or develop an uneven texture.

- Insufficient Curing Time: Soap needs adequate time to fully saponify and harden. This time varies depending on the recipe and the specific oils used. Longer curing periods in a cool, dry environment are often necessary for complete hardening. Monitoring the soap’s firmness through regular checks, potentially using a gentle pressure test, helps determine if sufficient time has passed.

- High Humidity: High humidity during the curing phase can prevent proper hardening. Proper ventilation and a well-ventilated, cool area are crucial to reduce moisture buildup around the soap. Consider placing the soap in a well-ventilated area, away from any sources of moisture, such as damp walls or leaking pipes.

- Incorrect Oil Ratios: An imbalance in the oil ratios can result in a soap that does not harden appropriately. Following the recipe meticulously is essential to ensure the right balance of oils and maintain the proper saponification process. Consult the recipe’s instructions to confirm the correct oil ratios. Adjusting the oil ratios might be necessary to achieve optimal results. For instance, adding a small amount of extra oils could address issues with insufficient hardness, and vice-versa.

Addressing Unpleasant Soap Textures

A soap’s texture significantly impacts its use and overall appeal. Problems such as a grainy or crumbly texture can stem from improper mixing, poor saponification, or contamination.

- Grainy or Crumbly Texture: This often results from incomplete saponification, implying that the oils and lye haven’t fully reacted. A more thorough mixing process during the saponification phase can resolve this. Ensure the lye solution is properly dissolved into the oils before adding additional ingredients to avoid any uneven distribution of the lye.

- Streaky or Uneven Texture: This is often due to inconsistent mixing. Mixing the oils and lye solution thoroughly, ensuring all components are fully incorporated, is crucial. A properly functioning and clean mixing equipment can ensure a consistent mixing process. Consider using a stand mixer or hand mixer for the proper mixing of the oils and lye solution, taking note of the proper mixing time.

- Contamination: Contamination, whether from impurities in the oils or the equipment, can affect the texture. Proper hygiene during the entire soap-making process, ensuring clean equipment and using fresh, high-quality ingredients, is essential. Thoroughly clean your mixing tools and equipment to avoid cross-contamination from previous batches or other materials.

Identifying and Resolving Soap-Making Issues: A Troubleshooting Guide

| Problem | Possible Cause | Solution |

|---|---|---|

| Soap not hardening | Insufficient curing time, high humidity, incorrect oil ratios | Increase curing time, maintain a cool, dry environment, adjust oil ratios per recipe |

| Grainy or crumbly texture | Incomplete saponification, improper mixing | Ensure complete saponification, mix oils and lye thoroughly |

| Streaky or uneven texture | Inconsistent mixing, contamination | Thorough mixing, clean equipment, fresh ingredients |

Soap Storage and Care: How To Make Soap Without Palm Oil

Proper storage is crucial for maintaining the quality and longevity of palm oil-free soap, ensuring its effectiveness and aesthetic appeal. Ignoring these guidelines can lead to premature deterioration, impacting the bar’s texture, scent, and ultimately, its user experience. Maintaining ideal storage conditions optimizes the soap’s performance and extends its usable lifespan.

Effective storage practices, encompassing both the environment and handling techniques, are vital to preserving the integrity of palm oil-free soap. These methods minimize exposure to factors that accelerate degradation, like moisture, extreme temperatures, and direct sunlight. Proper handling prevents damage to the bar’s surface, maintaining its aesthetic appeal and preserving its structural integrity.

Ideal Storage Environment

Maintaining a consistent environment for soap storage is essential to preventing moisture buildup and maintaining its structural integrity. Excessive moisture can lead to the soap becoming soft, mushy, or even moldy. Similarly, extreme temperatures, both hot and cold, can cause the soap to become brittle or lose its lathering properties.

Handling and Care

Gentle handling is key to preventing damage to the soap’s surface. Avoid harsh scrubbing or rough contact that can create unsightly scratches or damage the bar’s integrity. Proper wrapping or storage containers can minimize the risk of abrasion. Soap bars should be stored in a cool, dry place, away from direct sunlight.

Prolonging Shelf Life

Implementing appropriate storage methods significantly impacts the longevity of palm oil-free soap. Avoiding exposure to moisture and maintaining a stable temperature range are critical factors in extending its shelf life. Using appropriate containers and wrapping techniques can also contribute to the overall lifespan of the product.

Storage Methods and Suitability

| Storage Method | Suitability for Soap | Details |

|---|---|---|

| Paper Bags | Good | Lightweight and breathable, allowing for air circulation. However, not ideal for completely preventing moisture absorption. |

| Airtight Containers | Excellent | Minimizes moisture ingress, preserving the soap’s condition. Choose materials resistant to moisture. |

| Plastic Wrap | Fair | Provides a barrier against dust and some moisture. However, complete air circulation is hindered. Not ideal for long-term storage. |

| Glass Jars | Excellent | Durable and resistant to moisture. Allows for easy viewing and handling. Suitable for long-term storage. |

| Wooden Boxes | Good | Offers a natural and protective barrier. Suitable for storing multiple bars of soap, but not completely moisture-proof. |

Creating Unique Soap Variations

Beyond the basic bar, palm oil-free soap offers a canvas for creativity. Transforming a simple soap base into a unique and personalized product is achievable through careful consideration of color, scent, and form. This exploration delves into the diverse possibilities available to soap makers seeking to stand out in the market.

The versatility of palm oil-free soap allows for the incorporation of various elements to create distinctive and visually appealing products. This customization extends to the addition of natural colors, unique shapes, and appealing embellishments, catering to specific aesthetic preferences and brand identities.

Color Enhancement Methods

Natural food coloring agents are ideal for palm oil-free soap. These options provide vibrant hues without compromising the soap’s natural properties. For instance, beetroot juice yields a rich crimson, while spirulina powder offers a vibrant blue. Carefully selected natural pigments are crucial for safety and aesthetic appeal. Using too much coloring agent can lead to an uneven or unnatural appearance in the finished product.

Scent Infusion Techniques

Essential oils and fragrance oils offer a wide spectrum of aromatic possibilities. These additions not only enhance the scent but also contribute to the overall sensory experience of using the soap. The concentration of essential oils should be carefully balanced to avoid overwhelming or irritating the user. Blending different essential oils can create complex and unique fragrances, offering an opportunity for customization.

Shape and Embellishment Considerations

The shape and design of a soap bar significantly impact its visual appeal. Molding soap into intricate shapes, such as flowers, animals, or geometric patterns, elevates its aesthetic value. For example, using a decorative mold can produce soap bars with raised designs or sculpted textures.

Embellishment Suitability for Palm Oil-Free Soap

- Dried Flowers and Herbs: Adding dried flowers or herbs provides a natural touch. Ensure the chosen elements are completely dry to prevent moisture issues within the soap. The colors and textures add visual appeal and a sense of nature to the soap bar.

- Seashells and Small Stones: Incorporating small seashells or smooth stones can create a unique and visually interesting soap bar. These additions are particularly suitable for soaps intended to evoke a beach or ocean theme.

- Natural Pigments: Adding natural pigments (like clays or powders) allows for creative color variations. These are a great way to incorporate vibrant and natural hues into the soap bar.

- Metallic Flakes: These can add a glamorous touch to the soap bar, offering a unique shimmer. However, these can sometimes be prone to clumping in the soap and might not be ideal for all soap bases.

- Glitter and Sparkle: These embellishments add a touch of sparkle and shine, making the soap bar visually captivating. The type of glitter used should be compatible with the soap base.

Safety Precautions in Soap Making

Crafting luxurious, palm-oil-free soaps requires meticulous attention to safety. Improper handling of ingredients and equipment can lead to chemical burns, allergic reactions, and other health hazards. Adhering to strict safety protocols is paramount to a safe and enjoyable soap-making experience.

Proper safety measures, including the selection of appropriate protective gear and the correct disposal of materials, are critical for both personal well-being and environmental stewardship. Understanding the potential risks and implementing preventative measures will minimize hazards and maximize the enjoyment of this creative process.

Ingredient Handling Safety

Thorough knowledge of the chemical properties of soap-making ingredients is crucial. Some ingredients, like lye, are highly caustic and can cause severe burns if mishandled. Always handle lye with extreme care, using gloves, eye protection, and a well-ventilated area. Follow manufacturer instructions carefully for all ingredients, paying close attention to potential skin irritants or allergens. Always conduct thorough research on any ingredient before introducing it into your soap-making process. Accurate measurement is essential. Incorrect measurements can alter the final product’s properties and safety.

Equipment Safety Precautions

Using appropriate equipment and maintaining its proper functionality is critical for safety. Ensure all equipment is clean and in good working order before use. Broken or damaged equipment can cause accidents or create unsafe conditions. Never use equipment beyond its intended purpose or capacity. Always follow the manufacturer’s instructions for equipment use. If in doubt, seek guidance from experienced soap makers or consult the manufacturer’s instructions.

Protective Gear Requirements

Wearing appropriate personal protective equipment (PPE) is indispensable during all stages of soap making. This includes but is not limited to gloves, eye protection, and long-sleeved clothing. Gloves should be impervious to the chemicals used in soap making, and eye protection should offer complete coverage to prevent splashes or accidental exposure. Choosing the correct material for gloves is critical. For instance, nitrile or latex gloves are suitable for handling lye and other caustic ingredients, while vinyl gloves might be sufficient for other tasks. Appropriate clothing will prevent skin contact with ingredients.

Waste Disposal Procedures

Proper disposal of soap-making materials is crucial for both environmental and personal safety. Lye solutions, in particular, must be disposed of properly to avoid contamination. Never pour lye solutions down the drain. Always follow local regulations for waste disposal. Consult your local waste management authorities for specific guidelines on how to dispose of soap-making materials and lye solutions.

Safety Guidelines Summary Table

| Stage of Soap Making | Safety Precautions |

|---|---|

| Ingredient Handling | Wear gloves, eye protection, and work in a well-ventilated area. Follow manufacturer instructions carefully. Accurate measurement is critical. |

| Equipment Use | Ensure equipment is clean and in good working order. Use equipment for its intended purpose. Follow manufacturer instructions. |

| Protective Gear | Wear appropriate gloves, eye protection, and long-sleeved clothing. Choose the right gloves for the task. |

| Waste Disposal | Never pour lye solutions down the drain. Follow local regulations for waste disposal. |

Crafting soap without palm oil presents an interesting alternative to traditional methods. Consumers increasingly seek sustainable options, and exploring palm oil-free recipes is gaining traction. The environmental impact of palm oil plantations, however, often overshadows the soap-making process. Palm oil plantation practices frequently lead to deforestation and biodiversity loss. Fortunately, numerous resources offer recipes and techniques for creating equally effective and aesthetically pleasing soaps using sustainable alternatives.

These methods offer a way to enjoy the benefits of soap without contributing to these issues.