How to start palm oil business – How to start a palm oil business presents a lucrative opportunity in a global market with evolving trends. This guide delves into the intricacies of establishing a successful palm oil enterprise, from meticulous market research to strategic financial management, and ultimately, sustainable practices.

Understanding the competitive landscape, supply chain dynamics, and regulatory hurdles is crucial. This comprehensive guide will walk you through each step, from identifying profitable product lines to ensuring ethical sourcing and production methods. Key elements like financial projections, legal compliance, and robust marketing strategies will also be explored. A detailed breakdown of production processes, operational efficiency, and sustainable practices will be presented.

Market Research & Analysis

The palm oil market, a global commodity, presents a complex landscape with significant growth potential. Understanding its intricacies, including global trends, competitive dynamics, and profitability variations, is crucial for any aspiring entrepreneur entering this sector. Accurate market research and analysis form the bedrock of a successful business strategy in this competitive space.

The market is driven by a diverse array of factors, from consumer demand for affordable cooking oil to industrial applications in various sectors. Analyzing these drivers and identifying potential growth areas is vital for navigating the intricacies of the palm oil market.

Global Market Trends

The global palm oil market exhibits a dynamic pattern, marked by fluctuations in production and consumption. Demand for palm oil is consistently high, primarily driven by its affordability and versatility. However, sustainability concerns and geopolitical factors have introduced challenges and complexities to the market.

Key Competitors

Several multinational corporations and local players dominate the palm oil industry. These companies employ sophisticated strategies, including vertical integration, branding, and cost-effective production methods, to secure market share.

- Cargill: A global commodity trading giant, Cargill possesses significant resources and extensive global reach. Their vast infrastructure and established supply chains provide them with a substantial advantage in the market.

- Wilmar International: This leading palm oil producer and trader has a global presence, benefiting from extensive operational experience. Their focus on optimizing production and logistics contributes to their competitiveness.

- IOI Corporation: A prominent player, IOI Corporation excels in the production and processing of palm oil, with a strong emphasis on sustainability and quality control.

Understanding the strengths, weaknesses, and strategies of these competitors is critical for developing a successful business plan and market positioning.

Palm Oil Product Types & Demand

Different palm oil products cater to diverse market segments. The demand varies depending on the specific application and end-user requirements.

- Crude palm oil (CPO): Used as a raw material in various industries, including food and biofuel production. Demand for CPO is heavily reliant on the downstream industries’ needs and price fluctuations.

- Palm kernel oil (PKO): A by-product of palm oil processing, PKO finds applications in the production of soaps, detergents, and other consumer products. Its demand is influenced by the market trends in these downstream industries.

- Palm stearin: A refined component of palm oil, used in the production of margarine, chocolate, and other food products. Demand for palm stearin is driven by the consumer preference for cost-effective and readily available ingredients.

Profitability Analysis

Profitability in the palm oil market is contingent on various factors, including production costs, market prices, and operational efficiency. Factors such as sustainable practices and brand recognition can significantly impact profitability. No single product line offers guaranteed high returns; profitability depends on strategic positioning, market responsiveness, and effective cost management.

Projected Market Size & Growth

| Region | Projected Market Size (2024) | Projected Growth Rate (2024-2028) |

|---|---|---|

| Southeast Asia | $XX Billion | X% |

| Africa | $YY Billion | Y% |

| South America | $ZZ Billion | Z% |

| North America | $AA Billion | A% |

| Europe | $BB Billion | B% |

Note: Replace XX, YY, ZZ, AA, BB, X, Y, Z, A, B with accurate figures and percentages. Data sources should be explicitly cited.

Launching a palm oil business requires meticulous planning, from securing sustainable sourcing to navigating complex regulations. Understanding the nuances of supply chains and market demands is crucial. However, before diving in, it’s essential to consider the broader health implications of palm oil; a crucial aspect of the industry is the ongoing debate surrounding its potential health effects.

Consumers are increasingly scrutinizing ingredients, and a thorough understanding of is palm oil bad for you is paramount for any aspiring entrepreneur. Ultimately, successful palm oil ventures rely on robust market analysis and a keen awareness of consumer preferences, including their evolving health concerns.

The table above provides a general framework; specific values require detailed market research and analysis.

Business Plan Development

A robust business plan is crucial for navigating the complexities of launching a palm oil business. It serves as a roadmap, outlining the strategic direction, financial projections, and potential challenges. A well-structured plan attracts investors, secures funding, and provides a framework for operational efficiency. This is particularly important in the competitive palm oil market.

Developing a comprehensive business plan goes beyond simply documenting goals. It requires meticulous analysis of the market, financial feasibility, and potential risks. A strong plan positions the business for success by clearly articulating the intended trajectory and addressing potential roadblocks.

Mission, Vision, and Objectives

Defining the mission, vision, and objectives sets the strategic direction for the palm oil business. The mission statement encapsulates the core purpose and values. The vision statement paints a picture of the desired future state. Objectives, on the other hand, translate the vision into specific, measurable, achievable, relevant, and time-bound (SMART) targets.

- The mission statement should clearly articulate the business’s purpose, target audience, and commitment to sustainability.

- The vision statement should Artikel the long-term aspirations, including market leadership, expansion, and positive social impact.

- Well-defined objectives, such as achieving a specific market share or increasing production capacity within a defined timeframe, are essential for tracking progress.

Financial Projections

Accurate financial projections are paramount for securing funding and assessing the business’s viability. These projections provide a realistic outlook on startup costs, operating expenses, and projected revenue streams. A realistic assessment of potential challenges and mitigating strategies is vital for long-term sustainability.

| Category | Description | Example |

|---|---|---|

| Startup Costs | Includes land acquisition, equipment purchase, permits, and initial working capital. | $500,000 for land, equipment, and initial inventory. |

| Operating Expenses | Covers raw materials, labor, utilities, and marketing. | $100,000 per month for operational costs. |

| Revenue Forecasts | Predicts future income based on projected sales volume and pricing strategies. | Anticipating $1 million in revenue within the first year, with a 15% growth rate in subsequent years. |

Risks and Challenges

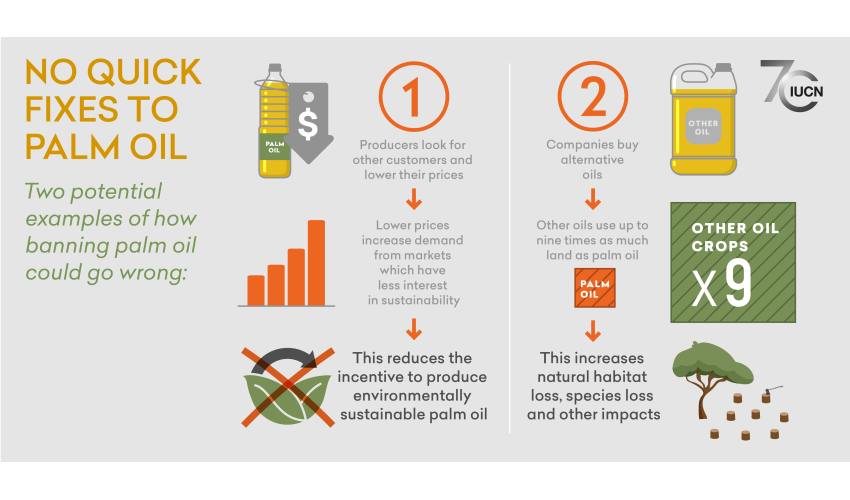

Starting a palm oil business presents unique challenges. These range from fluctuating commodity prices to environmental concerns and regulatory compliance. A proactive approach to risk mitigation is critical for long-term success.

- Price Volatility: Palm oil prices are susceptible to global market fluctuations, affecting profitability. Hedging strategies can mitigate this risk.

- Environmental Concerns: Deforestation and unsustainable practices can damage reputation and lead to regulatory scrutiny. A commitment to sustainable practices is vital.

- Regulatory Compliance: Navigating complex environmental and labor regulations is essential. Strong legal counsel and compliance expertise are vital.

- Competition: The palm oil market is competitive. Differentiation strategies, such as emphasizing sustainability or quality, can be key.

Funding Sources and Strategies

Securing funding is crucial for establishing a palm oil business. This includes exploring various avenues, from loans and grants to private equity and venture capital. A well-prepared business plan is paramount in attracting investment.

- Bank Loans: Traditional loans require strong financial projections and collateral.

- Grants: Government grants may be available for sustainable agriculture projects.

- Venture Capital: Attracting venture capital requires a compelling business plan and a clear understanding of the market.

- Angel Investors: Angel investors can provide capital and mentorship.

Sample Business Plan Structure

A well-organized business plan comprises key sections for clarity and impact.

| Section | Description |

|---|---|

| Executive Summary | Provides a concise overview of the business, its goals, and financial projections. |

| Company Description | Details the business’s mission, vision, and legal structure. |

| Market Analysis | Analyzes the target market, competition, and industry trends. |

| Financial Projections | Includes startup costs, operating expenses, and revenue forecasts. |

Sourcing & Supply Chain Management

Securing a reliable palm oil supply chain is paramount for a successful business. This crucial aspect extends beyond simply acquiring the raw material; it encompasses navigating the complexities of the global palm oil market, ensuring ethical sourcing, and building robust relationships with suppliers. A well-managed supply chain minimizes risks, enhances profitability, and strengthens the company’s reputation.

A robust supply chain is essential for a palm oil business. It encompasses everything from the initial sourcing of the raw material to the final delivery of the finished product, demanding careful consideration of sustainability, cost-effectiveness, and quality control. Effective supply chain management is key to maintaining profitability and market competitiveness in the palm oil industry.

Palm Oil Sourcing Methods

Diverse sourcing methods exist, each with its own set of advantages and disadvantages. Direct procurement from farms allows for greater control over quality and sustainability but often involves higher upfront costs and logistical complexities. Collaborations with suppliers provide access to established networks and potentially lower costs, but require careful vetting to ensure ethical practices. Importing from other regions offers access to diverse sources and potentially lower costs, but carries risks associated with international trade and quality variations.

- Direct Procurement from Farms: This method offers unparalleled control over the production process, enabling businesses to enforce ethical and sustainable practices directly at the source. However, it typically involves higher upfront costs and requires extensive due diligence in selecting farms committed to sustainability.

- Collaborations with Suppliers: Working with established suppliers allows for access to extensive networks, potentially reducing costs and increasing efficiency. However, it necessitates stringent vetting to confirm compliance with ethical and sustainability standards.

- Importing from Other Regions: Importing palm oil from other regions provides access to diverse sources and potentially lower costs. However, it introduces risks related to international trade, potential quality variations, and complexities in ensuring compliance with local regulations.

Sustainable and Ethical Sourcing Practices

The palm oil industry faces significant environmental and social challenges, demanding a commitment to sustainable and ethical sourcing. Deforestation, biodiversity loss, and labor exploitation are crucial concerns that companies must address proactively. Transparency in the supply chain is essential to demonstrate commitment to ethical sourcing, building consumer trust and mitigating reputational risks.

- Compliance with Certifications: Utilizing certifications like RSPO (Roundtable on Sustainable Palm Oil) is vital for demonstrating a commitment to sustainable practices and building consumer trust.

- Supply Chain Transparency: Implementing robust traceability systems is critical to ensure accountability throughout the supply chain, allowing consumers to track the origin and production methods of the palm oil.

- Community Engagement: Engaging with local communities affected by palm oil production is essential to ensure that the benefits of the industry are shared fairly and that any negative impacts are minimized.

Identifying Potential Suppliers

Selecting reliable suppliers is critical for a smooth and efficient supply chain. Key factors include their experience, reputation, and commitment to sustainable practices. Careful due diligence is necessary to identify suppliers who align with the company’s values and operational requirements.

- Experience and Reputation: Assessing the supplier’s history and reputation is crucial for determining their reliability and ability to meet contractual obligations.

- Sustainability Practices: Evaluating the supplier’s commitment to sustainable and ethical practices is paramount for aligning with the company’s values and avoiding reputational damage.

- Financial Stability: Evaluating the financial stability of potential suppliers is essential to minimize the risk of disruptions or defaults.

Establishing a Reliable Supply Chain

Building a robust and reliable supply chain involves meticulous planning, strategic partnerships, and proactive risk management. Establishing clear communication channels, implementing robust quality control measures, and diversifying sourcing options are crucial for mitigating risks.

- Clear Communication Channels: Establishing clear communication channels between the business and its suppliers is essential for efficient coordination and timely resolution of issues.

- Quality Control Measures: Implementing robust quality control measures at each stage of the supply chain is essential for maintaining product consistency and safety.

- Diversification of Sourcing Options: Diversifying sourcing options helps mitigate risks associated with disruptions in a particular region or with a specific supplier.

Sourcing Options Comparison, How to start palm oil business

| Sourcing Option | Cost | Quality | Sustainability |

|---|---|---|---|

| Direct Procurement from Farms | High | High | High (with proper due diligence) |

| Collaborations with Suppliers | Medium | Medium | Medium (depending on supplier) |

| Importing from Other Regions | Low | Medium (variable) | Variable (depending on region and practices) |

Production & Processing

From harvesting fresh fruit bunches to producing refined palm oil, the production process is a complex interplay of meticulous steps. Optimizing this process is critical for profitability and maintaining product quality. This requires careful consideration of each stage, from the initial harvest to the final product, to ensure consistent quality and efficiency.

The journey from raw fruit to refined palm oil involves a series of crucial steps, requiring specialized equipment and a robust supply chain. Efficient management of this process is paramount for a successful palm oil business. High hygiene standards and safety protocols are vital to maintain product quality and prevent contamination.

Harvesting and Initial Processing

The quality of the final palm oil product begins with the harvest. Proper harvesting techniques are crucial to minimize damage to the fruit bunches and ensure minimal loss of oil during processing. Early morning harvesting, when the fruit is at its optimum ripeness, is often preferred to maintain fruit integrity. A skilled workforce and suitable harvesting equipment are essential to maintain efficiency and quality. The harvested fruit is then transported to the processing facility as quickly as possible to prevent spoilage.

Fruit Bunch Preparation and Extraction

This phase involves meticulously preparing the harvested fruit bunches for the extraction process. Careful sorting and cleaning are required to remove any debris or unwanted materials. The removal of damaged or diseased fruit bunches is critical for maintaining product quality and preventing contamination. This stage typically involves a combination of manual and automated processes, depending on the size of the operation.

Oil Extraction

Several methods are employed for extracting the oil from the prepared fruit. The most common method is mechanical pressing, where the fruit pulp is pressed to extract the oil. Modern mills use sophisticated equipment to maximize oil extraction and minimize waste. The oil extracted at this stage is often referred to as crude palm oil (CPO).

Refining

Refining is a critical step in transforming crude palm oil into a usable product. Various refining methods exist, each with its impact on the final product’s quality.

| Refining Method | Impact on Final Product Quality |

|---|---|

| Solvent Extraction | Produces a higher-quality refined oil with a lower free fatty acid content, but solvent residue is a concern. |

| Alkaline Refining | Reduces the free fatty acid content significantly, resulting in a more stable and usable oil, but careful control of alkali is necessary to avoid off-flavors. |

| Bleaching | Removes impurities and color pigments, resulting in a clearer and more appealing product. |

| Deodorization | Eliminates undesirable odors and flavors, resulting in a more palatable and versatile oil. |

Hygiene and Safety Standards

Maintaining strict hygiene and safety protocols throughout the production process is paramount. Regular cleaning and sanitization of equipment and facilities are essential to prevent contamination. Training employees on proper hygiene practices and ensuring adequate personal protective equipment (PPE) is crucial. Compliance with food safety regulations and certifications (e.g., ISO 22000) is critical for maintaining market access and consumer confidence.

Setting Up a Palm Oil Processing Facility

A step-by-step procedure for establishing a palm oil processing facility includes:

- Site selection and obtaining necessary permits and licenses.

- Procuring land and establishing infrastructure.

- Installing and commissioning processing equipment, including presses, filters, and refining units.

- Hiring and training personnel on the various production stages.

- Establishing quality control measures and adhering to hygiene standards.

- Ensuring compliance with environmental regulations.

Technical Specifications for Processing Equipment

The technical specifications of the equipment will vary depending on the scale of the operation. Critical equipment includes:

| Equipment | Technical Specifications |

|---|---|

| Presses | Capacity (tonnes/hour), pressure (bar), and type of press (e.g., hydraulic, screw). |

| Filters | Capacity (tonnes/hour), filter media type, and pressure drop. |

| Refining units | Capacity (tonnes/hour), type of refining method, and size of vessels. |

| Deodorization units | Capacity (tonnes/hour), temperature control, and vacuum system. |

Legal & Regulatory Compliance: How To Start Palm Oil Business

Navigating the palm oil industry requires meticulous adherence to a complex web of legal and regulatory frameworks. Failure to comply can lead to significant financial penalties, reputational damage, and even legal action. This section Artikels the crucial aspects of legal and regulatory compliance for a successful palm oil enterprise.

The palm oil sector, globally significant for food and biofuel production, faces evolving regulations concerning sustainability, environmental impact, and labor practices. Companies operating in this domain must proactively understand and adapt to these requirements to ensure long-term viability and maintain a positive public image.

Essential Permits and Licenses

Obtaining the necessary permits and licenses is paramount for lawful operation. This involves understanding local, national, and potentially international regulations governing the cultivation, processing, and transportation of palm oil. Different jurisdictions have distinct requirements, necessitating thorough research into the specific regulations applicable to the intended operational location.

- Specific licenses for land use and cultivation are typically required, particularly in regions where land rights are tightly regulated. This includes adhering to zoning regulations and potentially obtaining permits for specific cultivation methods.

- Processing facilities often need specific permits related to waste disposal, emissions, and water usage, reflecting environmental protection concerns.

- Transportation permits may be required, especially for bulk shipments of palm oil products, to comply with road safety and environmental regulations.

Environmental Regulations

Environmental considerations are increasingly critical in the palm oil industry. Deforestation, peatland degradation, and water pollution are significant concerns. Companies must implement strategies to mitigate these impacts.

- Regulations regarding deforestation and peatland conservation are stringent and vary by region. Companies must adhere to these policies, often including obtaining certifications to demonstrate compliance with sustainable practices.

- Stricter water discharge regulations are prevalent, demanding careful management of wastewater treatment and pollution control measures.

- Emission standards for processing facilities are critical. Companies must implement efficient technologies to minimize emissions and comply with air quality standards.

Government Agencies and Their Roles

Understanding the roles of relevant government agencies is crucial for navigating the regulatory landscape. These agencies oversee compliance and enforcement.

- National environmental agencies play a pivotal role in setting and enforcing regulations related to deforestation, emissions, and water usage. Their involvement in monitoring and auditing operations is critical.

- Agricultural ministries and departments often oversee agricultural practices and land use permits.

- Customs and excise authorities are involved in ensuring compliance with import/export regulations and tax obligations.

Legal Implications of Sustainable Practices

Sustainable practices are no longer optional but rather a crucial aspect of legal compliance. Failure to meet these standards can lead to legal challenges and reputational harm.

- Companies pursuing sustainable palm oil certifications are better positioned to avoid legal disputes and maintain a positive public image.

- Compliance with international standards, such as Roundtable on Sustainable Palm Oil (RSPO), demonstrates a commitment to ethical and environmentally sound practices.

- Growing consumer awareness and demand for sustainable products influence legal frameworks, making sustainability a significant legal factor in the palm oil industry.

Importance of International Standards and Certifications

International standards and certifications are vital for ensuring global competitiveness and building consumer trust. Compliance demonstrates commitment to quality and sustainability.

- Certifications like RSPO (Roundtable on Sustainable Palm Oil) provide a globally recognized benchmark for sustainable palm oil production.

- Achieving and maintaining these certifications require demonstrable adherence to stringent environmental, social, and governance (ESG) criteria.

- Certifications enhance a company’s credibility and competitiveness in global markets.

Essential Legal Documents and Regulations

| Category | Description |

|---|---|

| Permits & Licenses | Land use permits, cultivation permits, processing permits, transportation permits |

| Environmental Regulations | Deforestation regulations, peatland conservation, water discharge standards, emission standards |

| Labor Laws | Minimum wage, working conditions, safety regulations |

| International Standards | RSPO certification, other relevant industry standards |

Marketing & Sales Strategies

A robust marketing and sales strategy is crucial for the success of any palm oil business. This involves not only attracting customers but also building a brand identity that resonates with target markets and fosters long-term loyalty. Effective strategies encompass a wide range of activities from establishing a unique brand to implementing efficient sales channels.

Branding and Positioning

Establishing a strong brand identity is paramount for a palm oil business. This involves crafting a compelling brand story that articulates the value proposition of the product, highlighting its quality, sustainability initiatives, and ethical sourcing practices. A well-defined brand will differentiate the product in a competitive market, fostering customer trust and loyalty. Consider using eco-friendly packaging and emphasizing sustainable practices in the brand narrative. For example, a brand emphasizing sustainable harvesting practices can appeal to environmentally conscious consumers.

Target Market Identification and Segmentation

Identifying and segmenting target markets is essential for tailoring marketing campaigns effectively. This process involves analyzing demographics, psychographics, and buying behaviors of potential customers. For instance, targeting consumers concerned about health and wellness might emphasize the nutritional benefits of palm oil, while targeting industrial buyers might focus on its cost-effectiveness and versatility. A detailed market analysis will reveal the specific needs and preferences of each segment, enabling the creation of customized marketing campaigns.

Marketing Campaigns and Promotional Activities

Comprehensive marketing campaigns should encompass a blend of advertising, public relations, and content marketing strategies. Advertising campaigns should leverage various channels, including online platforms, print media, and television, to reach the target audience effectively. Public relations initiatives can generate positive media coverage, enhance brand visibility, and build trust among consumers. Content marketing can be used to share valuable information about palm oil, addressing consumer concerns and highlighting the product’s benefits. For instance, partnering with food bloggers to showcase palm oil in recipes can generate significant engagement and brand awareness.

Sales Channels and Distribution

The choice of sales channels should align with the target market and business goals. This might involve direct sales, online platforms, partnerships with retail stores, and wholesale distribution agreements. Online platforms offer a cost-effective way to reach a wider customer base, while retail stores can provide access to a broader consumer segment. Wholesale partners can enable efficient distribution across a larger geographical area. Effective sales channels are critical for ensuring timely and convenient product access for customers.

Building Customer Relationships

Building strong customer relationships is crucial for long-term success. This includes providing excellent customer service, promptly addressing concerns, and actively seeking feedback. Regular communication with customers can foster loyalty and encourage repeat purchases. Loyalty programs and exclusive offers can also be implemented to reward loyal customers. For example, a loyalty program offering discounts or exclusive content for frequent buyers can significantly boost customer retention.

First-Year Marketing Plan

| Month | Activity | Target |

|---|---|---|

| 1-3 | Brand awareness campaign via social media and targeted advertising. | Reach 10,000 potential customers. |

| 4-6 | Develop partnerships with key retailers. | Establish presence in 5 major retail stores. |

| 7-9 | Launch online store and initiate online sales. | Achieve 15% of total sales online. |

| 10-12 | Implement influencer marketing campaigns and focus on customer testimonials. | Generate 20 positive customer reviews. |

Operations Management

A successful palm oil business hinges on efficient operations. Effective inventory control, quality assurance, and customer service are paramount to profitability and maintaining a positive brand image. Streamlining these processes with technology and a well-defined complaint resolution system is crucial for long-term success. A robust operational framework allows the company to adapt to market fluctuations and maintain consistent output.

Operational efficiency is directly tied to profitability and market competitiveness. Optimizing processes, ensuring product quality, and managing customer interactions effectively are key components of a successful palm oil business. These aspects are not merely supplementary; they are integral to the overall business strategy.

Inventory Control

Maintaining optimal inventory levels is critical to minimizing storage costs, preventing spoilage, and ensuring timely delivery. A robust inventory management system is essential for tracking stock levels, forecasting demand, and optimizing purchasing decisions. This system should integrate with the supply chain management process to ensure timely replenishment and minimize disruptions. Real-time data on stock levels and anticipated demand allows for proactive adjustments to prevent stockouts or excess inventory.

Quality Assurance

Consistent quality is paramount in the palm oil industry. A robust quality assurance program ensures that products meet established standards and consumer expectations. This program should encompass every stage of the process, from raw material sourcing to final product packaging. Regular testing and quality checks at each stage are vital for identifying and rectifying any deviations from the specified quality standards. Quality control should also include measures for ensuring traceability throughout the supply chain.

Customer Service

Customer satisfaction is crucial for long-term business success. A well-defined customer service protocol is essential for addressing customer inquiries, complaints, and feedback promptly and efficiently. Customer service representatives should be trained to handle complaints professionally and effectively resolve issues. The establishment of a dedicated customer service channel, such as a toll-free number or email address, enhances accessibility and responsiveness. Collecting and analyzing customer feedback can identify areas for improvement in the production and delivery processes.

Operational Metrics

Tracking key metrics is essential for monitoring operational efficiency and identifying areas for improvement. These metrics should include production output, inventory turnover rate, customer satisfaction scores, and complaint resolution time. Analyzing these metrics regularly allows for data-driven decisions to enhance operational efficiency and adapt to market demands. Key performance indicators (KPIs) should be clearly defined and regularly reviewed to measure progress towards operational goals. For instance, a high inventory turnover rate indicates efficient inventory management, while a low complaint resolution time signifies effective customer service.

Technology in Operations

Technology plays a vital role in streamlining palm oil business operations. Implementing enterprise resource planning (ERP) systems, automated inventory management software, and advanced quality control equipment can significantly enhance efficiency. Using digital tools for communication, data analysis, and decision-making can accelerate processes and reduce errors. Utilizing technology for real-time tracking of shipments and inventory levels can enhance supply chain visibility and responsiveness.

Customer Complaint Handling

A structured process for handling customer complaints is critical for maintaining customer satisfaction and addressing potential issues promptly. This process should include a clear escalation path, standardized response templates, and mechanisms for gathering feedback. A prompt and effective response to customer complaints can minimize negative publicity and build customer loyalty. Documentation of each complaint, resolution steps, and feedback is essential for continuous improvement.

Daily Operational Procedures (Flowchart)

| Step | Description |

|---|---|

| 1. Raw Material Receipt | Inspecting and recording the arrival of raw materials. |

| 2. Pre-Processing | Cleaning, sorting, and preparing the raw materials for processing. |

| 3. Processing | Carrying out the palm oil extraction process. |

| 4. Quality Control | Performing quality checks at each stage of processing. |

| 5. Packaging | Packaging the processed palm oil according to specifications. |

| 6. Inventory Management | Updating inventory levels and tracking stock. |

| 7. Dispatch/Delivery | Shipping the palm oil to customers. |

| 8. Customer Feedback Collection | Collecting and analyzing customer feedback for improvements. |

Financial Management

A robust financial management strategy is crucial for the long-term success of any palm oil business. Careful budgeting, cost control, and accurate financial reporting are essential to ensure profitability and sustainable growth. Effective financial management allows for informed decision-making, efficient resource allocation, and ultimately, maximizing returns.

Budgeting

A comprehensive budget is the cornerstone of financial planning. It Artikels projected revenues and expenses for a specific period, providing a roadmap for the business. A detailed budget for a palm oil business must account for variable costs (e.g., raw materials, labor) and fixed costs (e.g., rent, utilities). Forecasting future market trends and input costs is vital for creating an accurate and effective budget.

Cost Control

Cost control is critical for maintaining profitability in the palm oil industry. Implementing strategies to reduce unnecessary expenses while maintaining quality is paramount. This involves scrutinizing all operational expenses, negotiating favorable supplier contracts, and optimizing production processes. Analyzing variances between budgeted and actual costs helps identify areas for improvement and corrective action. Implementing lean manufacturing principles and process optimization strategies are crucial for cost reduction and efficiency improvement.

Financial Reporting

Accurate financial records and regular reporting are vital for transparency and accountability. Financial statements, including the income statement, balance sheet, and cash flow statement, provide a snapshot of the business’s financial health. These reports are essential for internal decision-making, attracting investors, and complying with regulatory requirements. Understanding these reports is crucial for identifying trends, assessing performance, and making informed business decisions.

Financial Tools and Strategies

Several financial tools and strategies can optimize profitability in the palm oil industry. For instance, discounted cash flow analysis can evaluate the profitability of capital investments. Cost-volume-profit analysis can illustrate how changes in costs and volume affect profits. Furthermore, using a financial forecasting model can predict future performance, aiding in strategic planning and decision-making. Analyzing competitor financial data can help the business understand the industry landscape and identify opportunities for improvement.

Methods for Monitoring and Controlling Expenses

Implementing a robust expense tracking system is crucial for monitoring and controlling costs. This involves meticulously recording all expenses, categorizing them, and regularly analyzing them against budgets. Utilizing accounting software can streamline the process, facilitating efficient data entry and reporting. Regular reviews of expense reports can reveal potential cost-saving opportunities. Implementing cost accounting methods such as activity-based costing can provide more accurate cost allocation and identification of areas for improvement.

Sample Financial Report

| Item | Description | Amount (USD) |

|---|---|---|

| Income Statement | ||

| Revenue | Sales of Palm Oil | 1,500,000 |

| Cost of Goods Sold | Raw Materials, Processing | 900,000 |

| Gross Profit | Revenue – Cost of Goods Sold | 600,000 |

| Operating Expenses | Rent, Utilities, Salaries | 200,000 |

| Net Income | Gross Profit – Operating Expenses | 400,000 |

| Balance Sheet | ||

| Assets | ||

| Current Assets | Cash, Inventory | 500,000 |

| Fixed Assets | Land, Equipment | 300,000 |

| Total Assets | 800,000 | |

| Liabilities & Equity | ||

| Current Liabilities | Accounts Payable | 200,000 |

| Long-term Liabilities | Loans | 100,000 |

| Equity | Owners’ Investment | 500,000 |

| Total Liabilities & Equity | 800,000 | |

| Cash Flow Statement | ||

| Cash Flow from Operations | Net Income, Adjustments | 450,000 |

| Cash Flow from Investing | Purchase of Equipment | -100,000 |

| Cash Flow from Financing | Debt Repayment | -50,000 |

| Net Increase in Cash | 300,000 |