Palm canal oil, a relatively lesser-known vegetable oil, is poised for a potential surge in demand. Derived from the palm tree, its extraction process and diverse applications are set to attract significant industry attention. Understanding its composition, properties, and environmental impact is crucial for navigating the emerging market.

This comprehensive overview delves into the intricacies of palm canal oil, exploring its origins, production methods, and applications across various sectors. From food processing to potential cosmetic uses, the article highlights the potential of this unique oil.

Palm Canal Oil: A Deep Dive

Palm canal oil, a relatively lesser-known vegetable oil, is gaining traction as a sustainable and potentially versatile alternative in various sectors. Its unique properties and extraction methods set it apart from other vegetable oils, prompting further investigation into its potential applications. This analysis delves into its origins, extraction, historical context, and potential future role.

Definition and Origin

Palm canal oil, also known as palm kernel oil, is a vegetable oil derived from the kernel of the fruit of the oil palm tree. The oil is extracted from the fibrous pulp that surrounds the seed kernel. Crucially, it’s distinct from palm oil, which is derived from the fruit flesh of the oil palm. The oil palm is a tropical tree, native to West Africa, but now cultivated in numerous tropical regions globally.

Extraction Process

The extraction process for palm canal oil involves several steps. First, the fruit is harvested and processed to separate the kernel from the fruit flesh. The kernels are then crushed and pressed to extract the oil. Advanced techniques like solvent extraction may also be used, depending on the desired quality and yield.

Historical Context and Use

Palm canal oil has been utilized for centuries in various applications. Traditionally, it was used in local communities for cooking and as a lubricant. Its presence in traditional medicine is also noted in some cultures. The oil’s use in modern times, however, is increasingly focused on its potential as a biofuel and ingredient in various products.

Synonyms and Alternative Names

While “palm canal oil” is the most common term, the oil is also known as palm kernel oil, and less frequently as palm nut oil. The interchangeable use of these names sometimes leads to confusion in the industry.

Properties and Potential Applications

Palm canal oil possesses a unique fatty acid profile, which may make it suitable for a range of applications. Its high content of saturated fats and low levels of polyunsaturated fats could make it a viable alternative in food processing, particularly in the production of certain types of margarine and other processed foods. Preliminary studies suggest potential applications in biofuel production and as a lubricant.

Sustainability Considerations

The cultivation and processing of palm canal oil, like other agricultural products, raise sustainability concerns. Responsible sourcing and sustainable agricultural practices are crucial to minimize the environmental impact and ensure long-term availability of this resource. Certification schemes and standards are emerging to help ensure responsible production.

Composition and Properties

Palm canal oil, a relatively less explored palm oil derivative, holds potential for diverse applications. Understanding its chemical composition and physical properties is crucial for evaluating its suitability in various sectors. Its unique characteristics compared to other vegetable oils could unlock new possibilities in industries ranging from biofuels to food processing.

The precise chemical composition of palm canal oil, a byproduct of palm oil processing, is largely determined by the specific extraction method and the original palm oil source. Its properties, including density, viscosity, and melting point, vary depending on the refining process and the specific composition of the fatty acids within the oil. This variability underscores the importance of standardized analysis for reliable assessment of its properties.

Chemical Composition

Palm canal oil, a byproduct of palm oil processing, is primarily composed of triglycerides, which are esters of fatty acids and glycerol. The specific fatty acid composition influences the oil’s properties. The presence of saturated and unsaturated fatty acids dictates the physical characteristics and potential applications.

Physical Properties

Palm canal oil exhibits specific physical properties that distinguish it from other vegetable oils. These properties are vital for determining its suitability in various applications. Density, viscosity, and melting point significantly influence its processing and end-use.

- Density: Palm canal oil’s density, typically ranging from 0.915 to 0.925 g/cm³, affects its handling and mixing in different formulations. It is generally slightly less dense than water, allowing for easier separation and handling during processing. This density difference is important in industrial settings where efficient separation is crucial.

- Viscosity: Viscosity, a measure of a fluid’s resistance to flow, plays a key role in processing and application. Palm canal oil’s viscosity is influenced by temperature and fatty acid composition. Viscosity can vary considerably, impacting the efficiency of machinery and overall process flow. For example, high viscosity can lead to clogging or require specialized equipment.

- Melting Point: The melting point of palm canal oil is a critical parameter, especially in applications involving cold temperatures or cold-chain logistics. A lower melting point allows for easier handling at lower temperatures, whereas a higher melting point ensures stability in warmer environments. This characteristic is particularly relevant for industrial applications requiring specific temperature ranges.

Comparison with Similar Oils

Compared to other vegetable oils like soybean or sunflower oil, palm canal oil exhibits distinct characteristics. The differing fatty acid profiles result in variations in density, viscosity, and melting points. This divergence in properties is crucial for understanding its unique suitability in specific applications. For example, the lower viscosity of some palm canal oils makes them suitable for certain lubricant formulations.

Key Components and Percentages

The following table provides a general overview of the key components present in palm canal oil and their approximate percentages. Note that these values can vary based on the extraction process and the original palm oil source.

| Component | Approximate Percentage (%) |

|---|---|

| Saturated Fatty Acids | 50-60 |

| Unsaturated Fatty Acids | 30-40 |

| Glycerol | ~10 |

| Other Components | <1 |

Applications and Uses

Palm canal oil, a relatively nascent but promising vegetable oil, is finding its niche across various industries. Its unique composition, characterized by a blend of saturated and unsaturated fatty acids, offers diverse functionalities, setting it apart from other vegetable oils. This versatility translates into a wide array of applications, from food processing to potential cosmetic use.

Industrial Applications

Palm canal oil’s properties make it suitable for a range of industrial applications. Its stability and relatively high smoke point allow for its use in frying and other high-heat processes, while its lubricating properties suggest potential in industrial machinery. The unique combination of its chemical components offers specific advantages for various manufacturing processes.

- Lubrication: Palm canal oil’s viscosity and lubricating properties make it a viable alternative to conventional lubricants in certain industrial applications. Its ability to reduce friction and wear in machinery components could lead to significant cost savings and environmental benefits compared to some petroleum-based lubricants. This is particularly important for industries concerned about sustainability.

- Biofuel Production: The potential of palm canal oil as a feedstock for biofuel production is an area of active research. Its high energy content and relatively straightforward processing procedures make it a promising alternative to fossil fuels. Pilot projects and preliminary studies suggest that palm canal oil can be processed into biofuels with a relatively high yield, further emphasizing its potential for renewable energy production.

Food Processing Applications

Palm canal oil’s stability and neutral flavor profile make it a compelling ingredient in food processing. Its ability to withstand high temperatures without significant degradation allows for its use in various culinary applications, from frying to baking. The oil’s high smoke point and stability are key factors in its suitability for food processing.

- Frying: Its high smoke point allows for extended frying periods without significant degradation of the oil’s quality. This makes it a suitable replacement for other vegetable oils in various frying applications, potentially lowering costs and improving sustainability.

- Baking: Palm canal oil’s consistency and texture contribute to improved product quality in baked goods. The neutral flavor profile of the oil ensures that the taste of the final product is not compromised. Preliminary trials show a positive impact on the structure and texture of baked goods, suggesting its potential for replacing other oils in this sector.

Cosmetic and Personal Care Applications

Preliminary research suggests potential applications of palm canal oil in cosmetics and personal care products. Its moisturizing and conditioning properties, combined with its ability to absorb into the skin effectively, might make it a viable alternative to other ingredients in lotions, creams, and other skin care products. This potential application hinges on further research into its long-term effects on skin health.

- Moisturizers: The oil’s capacity to hydrate and condition the skin could make it a beneficial component in moisturizing lotions and creams. Its potential for improved skin elasticity and softness could be significant.

- Hair Care: Some studies indicate that palm canal oil may possess conditioning properties suitable for hair care products. Its ability to smooth and condition hair could potentially lead to innovations in hair care products.

Examples of Industries Utilizing Palm Canal Oil

The nascent nature of palm canal oil’s utilization means a limited number of industries are currently actively incorporating it into their processes. However, preliminary trials and research suggest potential in several sectors. Further research and development are needed to expand its presence in these and other markets.

- Food Processing Industry: Companies involved in food production and processing are exploring palm canal oil as a potential alternative to conventional oils. Their interest is driven by the potential cost savings and sustainability benefits associated with palm canal oil.

- Biofuel Production: Startups and established companies focused on renewable energy are actively researching palm canal oil’s potential as a biofuel feedstock. Their focus is on developing sustainable and cost-effective biofuel solutions.

Applications and Benefits Table

| Application | Benefits |

|---|---|

| Industrial Lubrication | Reduced friction, wear, potential cost savings, and environmental benefits |

| Food Processing (Frying) | High smoke point, stability, potential cost savings |

| Food Processing (Baking) | Improved product texture and consistency, neutral flavor |

| Cosmetics (Moisturizers) | Hydrating and conditioning properties, potential for improved skin elasticity |

Production and Supply Chain

Palm canal oil, a byproduct of palm oil processing, is increasingly attracting attention for its potential as a sustainable and versatile feedstock. Understanding its production process and global supply chain is crucial to assessing its economic and environmental implications. The refining and processing of palm canal oil presents a complex interplay of economic incentives and ecological concerns.

The production of palm canal oil is inextricably linked to the larger palm oil industry, which faces ongoing scrutiny regarding sustainability and environmental impact. This interconnectedness highlights the importance of responsible practices throughout the entire supply chain.

Production Process

The production of palm canal oil begins with the processing of fresh fruit bunches (FFBs) in palm oil mills. The extraction of palm oil from the fruit pulp generates a significant byproduct: palm canal oil, which is rich in fatty acids. The process involves several stages, including pressing the fruit to separate the oil from the pulp, and subsequently, separating and refining the canal oil. Specific techniques may vary based on the scale of the operation and the desired quality of the final product.

- Fruit Bunch Processing: Palm fruit bunches are transported to the mill, where they are sorted, and the fruit is separated from the bunches. The fruit is then crushed and pressed to extract palm oil. This process generates palm canal oil as a byproduct.

- Canal Oil Separation: The palm canal oil is separated from the other components of the palm fruit residue. This typically involves a filtration process to remove impurities and sediment.

- Refining and Processing: The extracted palm canal oil undergoes further processing to remove any remaining impurities and achieve the desired quality standards. This may involve bleaching, deodorizing, and refining to improve color, odor, and overall quality.

Global Supply Chain

The global supply chain for palm canal oil is closely tied to the broader palm oil industry. Key players include major palm oil producers, processors, and traders, many of whom are multinational corporations. Southeast Asia, particularly Indonesia and Malaysia, is the dominant region in palm oil production, and therefore, also the primary source of palm canal oil. The demand for palm canal oil is increasing, creating opportunities for new players and businesses.

- Key Players: Multinational corporations and smaller regional players participate in the palm canal oil supply chain, from plantation management to refining and distribution. These companies are often involved in the broader palm oil supply chain.

- Regions: Southeast Asia, specifically Indonesia and Malaysia, is the dominant region for palm oil production, and thus, the source of the majority of palm canal oil. As demand for palm canal oil increases, other regions may see greater involvement in the production and processing stages.

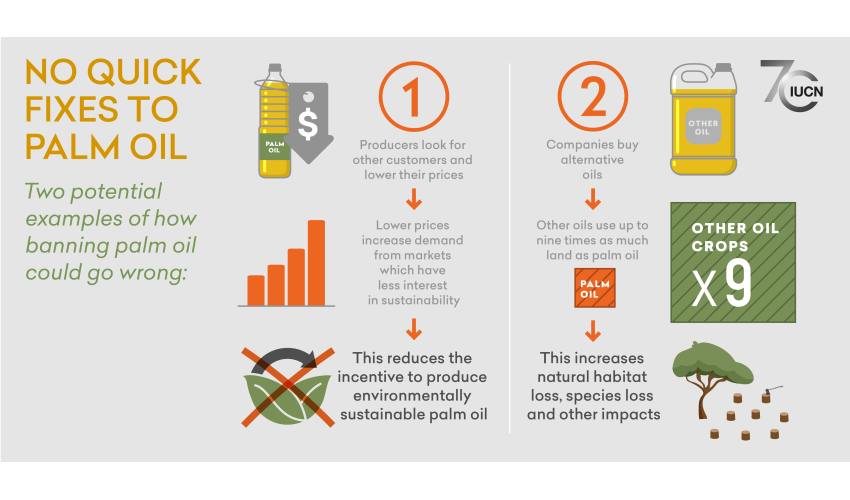

Sustainability Concerns

Palm canal oil production, like the wider palm oil industry, faces significant sustainability concerns. Deforestation, biodiversity loss, and social issues related to land use are common concerns. Furthermore, the environmental impact of the entire supply chain needs careful consideration.

- Deforestation: The expansion of palm oil plantations, including those for canal oil, often leads to deforestation, which contributes to habitat loss and climate change.

- Biodiversity Loss: The conversion of natural habitats to palm oil plantations has a detrimental impact on biodiversity, affecting numerous species of flora and fauna.

- Social Issues: Land acquisition issues, labor practices, and community engagement are critical considerations in ensuring a sustainable palm canal oil supply chain.

Flowchart of Palm Canal Oil Production

A flowchart illustrating the palm canal oil production process is presented below, but in textual format for better comprehension and ease of reading.

Step 1: Fresh Fruit Bunches (FFBs) are collected and transported to the palm oil mill.

Step 2: The FFBs are processed, separating the fruit from the bunches.

Step 3: Palm oil is extracted from the fruit pulp.

Palm canal oil, a byproduct of palm oil production, often raises sustainability concerns. Understanding the process of how palm oil is made, as detailed here , is crucial to evaluating its environmental impact. The refining methods and subsequent byproducts, including palm canal oil, significantly influence the industry’s overall footprint.

Step 4: Palm canal oil is separated from the remaining palm fruit residue.

Step 5: The palm canal oil is refined to meet quality standards.

Step 6: The refined palm canal oil is packaged and distributed.

Safety and Health Concerns: Palm Canal Oil

Palm canal oil, while presenting potential benefits in various applications, necessitates careful consideration of safety and health implications. Understanding the potential risks associated with its handling, consumption, and production is crucial for responsible use and minimizing adverse effects on human health and the environment.

Safety Guidelines for Handling Palm Canal Oil

Proper handling procedures are essential to mitigate risks during palm canal oil extraction, processing, and application. These guidelines should be meticulously followed to prevent accidents and ensure worker safety. Adherence to these protocols is critical for preventing potential harm.

- Personal Protective Equipment (PPE): Workers handling palm canal oil should consistently wear appropriate PPE, including gloves, eye protection, and protective clothing. This safeguards against skin contact, inhalation of oil vapors, and potential eye irritation. For example, nitrile gloves provide a barrier against chemical exposure, and safety glasses protect against flying debris or splashes.

- Ventilation and Air Quality: Adequate ventilation in processing areas is critical to minimize exposure to palm canal oil fumes. Monitoring air quality levels and implementing appropriate ventilation systems helps maintain healthy working conditions. Regular air quality checks should be conducted to ensure the safety of workers.

- Spill Management Procedures: Comprehensive spill management plans should be in place to address accidental spills of palm canal oil. These plans should Artikel protocols for containment, cleanup, and disposal of the spilled material to prevent environmental contamination and ensure worker safety.

- Storage and Handling Practices: Palm canal oil should be stored in properly labeled containers in designated areas. Proper storage prevents contamination, reduces the risk of spills, and ensures safe handling practices. Proper labeling and storage locations minimize risks.

Potential Health Risks of Palm Canal Oil

The potential health risks associated with palm canal oil consumption or exposure are a key consideration. While not extensively studied, the potential for adverse effects should not be overlooked.

- Allergic Reactions: Some individuals may exhibit allergic reactions or sensitivities to palm canal oil, leading to symptoms like skin rashes, itching, or respiratory distress. These reactions highlight the need for cautious handling and assessment of individual sensitivities.

- Toxicity Concerns: Limited research on the long-term toxicity of palm canal oil consumption warrants further investigation. Potential risks, such as liver or kidney damage, remain areas of concern that require further study. Animal studies are necessary to understand the long-term implications of prolonged exposure.

- Irritant Properties: Direct contact with palm canal oil can cause skin irritation in some individuals. This is a known irritant and appropriate precautions should be taken during handling to prevent skin contact.

Environmental Impacts of Palm Canal Oil Production

Palm canal oil production, like other agricultural activities, can have environmental consequences. Understanding these impacts is essential for sustainable practices.

- Deforestation: Conversion of natural habitats, such as rainforests, for palm canal oil plantations can lead to deforestation, habitat loss, and biodiversity reduction. The loss of biodiversity poses a significant threat to the ecological balance. Sustainable practices are crucial to minimize the impact on these vital ecosystems.

- Water Usage: Palm canal oil production requires substantial water resources for various processes. Over-extraction of water resources can impact local water supplies and ecosystems. Water conservation strategies are necessary to minimize the environmental footprint.

- Soil Degradation: Intensive farming practices associated with palm canal oil production can lead to soil degradation, impacting agricultural productivity and water quality. Soil degradation is a major environmental concern that requires attention.

Regulations and Standards Governing Palm Canal Oil

Regulations and standards for palm canal oil production and use vary across different countries and regions. A clear understanding of these regulations is crucial for adherence to standards and responsible production.

- Food Safety Standards: Regulations regarding palm canal oil usage in food products are vital to ensure consumer safety and quality control. Adherence to these standards protects consumers and ensures consistent quality.

- Environmental Regulations: Environmental regulations related to palm canal oil production often focus on minimizing deforestation, water usage, and pollution. These regulations aim to mitigate the environmental impact of palm canal oil production.

- Occupational Safety Standards: Occupational safety standards for palm canal oil production address worker safety and health concerns. These standards minimize risks during extraction, processing, and handling.

Known Allergies and Sensitivities

Allergies and sensitivities to palm canal oil are not extensively documented. However, potential allergic reactions warrant caution and further research.

Environmental Impact

Palm canal oil, a byproduct of palm oil production, faces scrutiny regarding its environmental footprint. While not a primary driver of deforestation like mature palm oil plantations, its extraction can still impact biodiversity and ecosystems, especially in regions with limited environmental regulations. The potential for unsustainable practices, including deforestation and habitat loss, demands careful consideration of the production chain.

Palm canal oil production, though often portrayed as a more sustainable alternative, still necessitates scrutiny. The extraction process, while not typically directly responsible for large-scale deforestation, can contribute to land use change if not managed responsibly. Examining the specific environmental impact requires a deep dive into production methods, including the role of responsible sourcing and sustainable practices.

Biodiversity and Ecosystem Impacts

Palm canal oil extraction, like any industrial activity, can have consequences for biodiversity. Disruption of natural habitats, including wetlands and forests, can lead to a decline in animal populations and species extinction. These impacts are amplified when the extraction occurs in regions with fragile ecosystems and limited regulatory oversight. Furthermore, the conversion of natural ecosystems to agricultural land for canal oil extraction can reduce the availability of essential resources for wildlife, such as food and water. Consequently, careful consideration of the ecological footprint is crucial in ensuring responsible palm canal oil production.

Deforestation and Land Use Change

The relationship between palm canal oil production and deforestation is complex. While not typically the primary driver of deforestation, palm canal oil extraction often occurs within existing palm oil estates. Expansion of these estates, driven by demand for palm canal oil, can contribute to habitat loss. This is particularly relevant in areas with weak environmental regulations, where the temptation to clear-cut forests for canal oil extraction may be higher. Moreover, the conversion of forests and wetlands for palm canal oil production can negatively impact carbon sequestration and water cycles. Sustainable practices are critical to mitigating these risks.

Sustainability Practices in Palm Canal Oil Production

Several sustainability initiatives are emerging in the palm canal oil industry. These include implementing responsible sourcing guidelines, adopting sustainable land management practices, and promoting the use of environmentally friendly extraction techniques. These efforts are vital in minimizing the environmental impact and ensuring long-term viability of the industry. The development of certification schemes for sustainable palm canal oil production is another critical step, providing consumers with transparency and confidence in the product’s origins.

Comparison of Sustainable and Unsustainable Palm Canal Oil Production

| Characteristic | Unsustainable Palm Canal Oil Production | Sustainable Palm Canal Oil Production |

|---|---|---|

| Land Use Change | Expansion of palm oil estates into natural habitats, often leading to deforestation. | Strict adherence to existing land use regulations, avoiding conversion of forests and wetlands. |

| Biodiversity Impact | Habitat loss and fragmentation, leading to declines in biodiversity and potentially threatening endangered species. | Conservation of existing habitats and mitigation of impacts on wildlife. |

| Environmental Regulations | Inadequate or non-existent environmental regulations. | Strict adherence to environmental regulations and standards. |

| Sourcing | Limited or no traceability of the source of palm canal oil, potentially including illegally sourced materials. | Rigorous traceability of the source, ensuring responsible sourcing. |

| Certification | Lack of certifications or compliance with unsustainable standards. | Adherence to recognized sustainability certifications (e.g., RSPO) for palm canal oil. |

Future Trends and Innovations

Palm canal oil, a relatively nascent biofuel, is poised for potential expansion beyond its current applications. Emerging research and evolving market dynamics suggest a trajectory of increasing demand, driven by the global push towards sustainable and renewable energy sources. This section explores the potential future uses, research trends, and innovations in production and processing, alongside predicted market developments.

The increasing awareness of environmental concerns and the growing emphasis on sustainable alternatives are catalysts for the exploration of palm canal oil’s potential. Innovations in production and processing methods are critical to realizing its full potential, ensuring cost-effectiveness and environmental responsibility.

Potential Future Applications and Uses

Palm canal oil, with its unique properties, presents a range of potential applications beyond its current uses. These include biofuel production, particularly in blended fuels, and as a feedstock for the production of specialty chemicals.

- Biofuel Blends: The use of palm canal oil as a component in biofuel blends is a promising avenue. This approach could significantly reduce reliance on fossil fuels and promote a more sustainable energy landscape. Examples of existing biofuel blending practices in other regions could provide valuable insights into optimal blending ratios and potential challenges.

- Specialty Chemicals: Palm canal oil’s chemical composition makes it a potential source for various specialty chemicals. This could open new markets and create opportunities for downstream processing and value addition. The potential for producing surfactants, lubricants, and other chemical derivatives from palm canal oil deserves further exploration.

Emerging Research and Development Trends

Research into palm canal oil is focused on optimizing its extraction, refining, and processing. This emphasis on efficiency and sustainability will be crucial for its widespread adoption.

- Improved Extraction Techniques: Researchers are exploring novel methods for extracting palm canal oil, aiming to improve efficiency and minimize environmental impact. This includes developing more sustainable solvent extraction processes and exploring alternative methods like supercritical fluid extraction.

- Enhanced Refining Processes: The refining process is critical for achieving the desired quality and purity of palm canal oil. Ongoing research seeks to optimize refining procedures to reduce processing costs and improve product quality, leading to a more refined and desirable product.

- Sustainability Considerations: Research emphasizes the sustainability of palm canal oil production. This includes examining the entire production chain, from cultivation to processing, to minimize environmental impact and ensure responsible resource management.

Potential Innovations in Production and Processing

Innovations in production and processing are essential to making palm canal oil a viable alternative. These include new technologies for sustainable cultivation, efficient extraction methods, and advanced refining processes.

- Sustainable Cultivation Practices: Sustainable cultivation practices are paramount. Research into optimized farming techniques and pest control methods can ensure the responsible and environmentally friendly sourcing of the raw material.

- Advanced Extraction Technologies: Exploring alternative extraction methods, such as enzyme-assisted extraction, is crucial for maximizing oil yield and reducing solvent usage. This could significantly reduce environmental impact compared to conventional methods.

- Integrated Refining Systems: Developing integrated refining systems that combine multiple processing steps in a single facility can optimize efficiency and reduce waste. This approach can lead to significant cost savings and a more sustainable process.

Future Market Trends and Demand

The future market for palm canal oil is contingent upon several factors. Continued research, development, and regulatory support will play a pivotal role in shaping its future.

- Government Policies and Regulations: Government policies and regulations regarding biofuels and sustainable practices will significantly influence the market’s growth trajectory. Favorable policies promoting biofuel adoption and sustainable sourcing will create a positive market environment.

- Consumer Awareness and Acceptance: Consumer awareness of sustainable alternatives and their willingness to adopt these products will directly impact the market demand. Education campaigns promoting the benefits of palm canal oil will play a key role.

- Technological Advancements: Continued advancements in extraction, refining, and processing technologies will significantly impact the cost-effectiveness and accessibility of palm canal oil, potentially increasing market adoption.