Palm kernel acid, a versatile fatty acid derived from palm kernels, is gaining traction in various industries due to its unique properties. This comprehensive overview delves into its chemical structure, sources, extraction methods, and applications, examining its economic significance and the associated safety and environmental considerations.

Palm kernel acid, a saturated fatty acid, boasts a wide range of applications, from food production to industrial processes. Its properties, including melting point, boiling point, and reactivity, are key determinants of its suitability for diverse purposes. This in-depth analysis will highlight the nuances of this important chemical.

Introduction to Palm Kernel Acid

Palm kernel acid, a crucial component in various industries, is a saturated fatty acid primarily derived from the kernels of oil palms. Its versatile nature allows for diverse applications, from food processing to industrial manufacturing. Understanding its chemical properties, sources, and historical context is vital for comprehending its significance in the global economy.

Palm kernel acid, a saturated fatty acid, plays a significant role in the production of various industrial products. Its chemical structure and properties influence its suitability for different applications.

Chemical Structure of Palm Kernel Acid

Palm kernel acid, like other fatty acids, possesses a long hydrocarbon chain with a carboxyl group (-COOH) at one end. Its specific structure contributes to its physical and chemical characteristics. The precise arrangement of carbon atoms and their associated hydrogen atoms within the hydrocarbon chain dictates the acid’s melting point, solubility, and overall behavior. For example, the degree of saturation impacts the rigidity and stability of the molecule.

The chemical structure of palm kernel acid is characterized by a long hydrocarbon chain with a carboxyl group at one end. A common representation of the chemical structure is C12H24O2.

Sources of Palm Kernel Acid

Palm kernel acid is extracted from the kernels of oil palms (Elaeis guineensis). The kernels are processed to yield palm kernel oil, which is then refined to isolate the fatty acids, including palm kernel acid. The specific varieties of oil palms, as well as cultivation practices, can affect the composition of the extracted oil and thus the resulting concentration of palm kernel acid.

Forms of Palm Kernel Acid

Palm kernel acid typically exists as a liquid or solid depending on the specific conditions. The form it takes can be influenced by factors such as temperature and pressure. This characteristic is relevant to its application in different industrial processes.

Historical Context of Palm Kernel Acid Use

The historical use of palm kernel acid dates back to traditional applications in various cultures. Its extraction and utilization have evolved alongside advancements in refining techniques. Over time, the demand for palm kernel acid has grown, reflecting its importance in diverse sectors. Its increasing use in various applications, especially in industrial processes, is a clear testament to its practicality and cost-effectiveness.

Types of Palm Kernel Acids

Understanding the different types of palm kernel acids and their properties is crucial for selecting the right product for specific applications.

| Acid Type | Chemical Formula | Molecular Weight (g/mol) | Common Uses |

|---|---|---|---|

| Palm Kernel Acid (PCA) | C12H24O2 | 204.35 | Soap production, lubricants, and some food applications |

| Isopalm Kernel Acid | C16H32O2 | 268.45 | Detergent manufacturing, cosmetic formulations, and biodiesel production |

| Stearic Acid | C18H36O2 | 304.52 | Candle making, lubricants, and food additives |

Properties and Characteristics

Palm kernel acid, a crucial component in the palm oil industry, exhibits a diverse range of physical and chemical properties that influence its applications and interactions with other materials. Understanding these characteristics is essential for optimizing its use in various sectors, from food processing to industrial applications.

Physical Properties

Palm kernel acid, like other fatty acids, exists in a solid state at room temperature, with a characteristic waxy texture. Its physical properties are intricately linked to its molecular structure and the presence of various chain lengths. The varying chain lengths and degrees of saturation affect its melting points, influencing its suitability for different applications. The density of palm kernel acid also plays a role in its processing and handling.

Chemical Properties

The chemical structure of palm kernel acid is primarily composed of long hydrocarbon chains terminating in a carboxyl group. This structure determines its reactivity and interactions with other chemicals. The presence of the carboxyl group allows for the formation of salts and esters, which are vital in various industrial processes. The degree of saturation, impacting the presence of double bonds in the hydrocarbon chain, is another critical factor determining the chemical properties.

Reactivity

Palm kernel acid, being a carboxylic acid, exhibits the typical reactivity associated with this class of compounds. It can undergo esterification reactions, forming esters with alcohols. The presence of double bonds in unsaturated palm kernel acids leads to potential oxidation reactions, which are crucial to consider during storage and processing. Understanding the reactivity of palm kernel acid is vital for controlling its interactions in industrial processes and maintaining its quality.

Comparison with Other Fatty Acids

Palm kernel acid shares similarities and differences with other fatty acids, particularly those derived from vegetable oils. The primary distinctions lie in their chain lengths, degrees of saturation, and consequently, their melting points, boiling points, and densities. These differences in properties directly impact their applications in various industries. Comparing these parameters reveals the unique characteristics of palm kernel acid and its potential uses.

Comparative Table of Properties

| Acid Type | Melting Point (°C) | Boiling Point (°C) | Density (g/cm³) |

|---|---|---|---|

| Palm Kernel Acid (saturated) | 30-40 | >300 (decomposes) | 0.91-0.93 |

| Palm Kernel Acid (unsaturated) | 20-30 | >300 (decomposes) | 0.90-0.92 |

| Stearic Acid | 69.3 | 383 | 0.912 |

| Oleic Acid | 13.4 | 287 | 0.890 |

Note: Values may vary based on specific chain lengths and degree of saturation within each type of palm kernel acid. The boiling points are approximate, as these fatty acids generally decompose before reaching their boiling point under standard conditions.

Production and Extraction Methods

Palm kernel acid, a crucial component in various industries, is derived from the kernels of oil palm fruits. The extraction process, encompassing several stages, involves separating the fatty acids from the palm kernel. Efficient and cost-effective extraction methods are essential for maximizing yield and minimizing environmental impact.

Palm Kernel Acid Extraction Process

The process of extracting palm kernel acid typically involves several steps, starting with the preparation of the palm kernels. These kernels are first processed to remove any impurities and then subjected to different extraction methods to isolate the desired fatty acids. The subsequent purification steps are critical in ensuring the quality and purity of the final product.

Kernel Preparation

Before extraction, palm kernels undergo meticulous preparation. This typically involves cleaning, crushing, and drying to remove excess moisture and impurities. The crushing process breaks down the kernels into smaller pieces, increasing the surface area available for extraction. Properly prepared kernels are crucial for efficient and effective extraction of palm kernel acid.

Extraction Methods

Various methods exist for extracting palm kernel acid, each with its own set of advantages and disadvantages. These methods vary in terms of efficiency, cost, and environmental impact. Solvent extraction, often using hexane, is a prevalent method due to its high efficiency in extracting the desired components.

Solvent Extraction

Solvent extraction, particularly using hexane, is a common method for extracting palm kernel acid. The crushed kernels are soaked in the solvent, which dissolves the fatty acids. The solvent is then separated from the extracted mixture, leaving behind the palm kernel acid. The solvent is recovered and reused in subsequent processes, minimizing waste.

Purification Methods

The extracted palm kernel acid mixture often contains impurities. Purification techniques are essential for obtaining a high-quality product. These techniques typically involve multiple stages of separation, such as filtration, distillation, and crystallization. Different purification methods can affect the final product’s purity and cost-effectiveness.

Purification Techniques

Common purification techniques include fractional distillation, which separates components based on their boiling points, and crystallization, which isolates the palm kernel acid through solidification. These processes ensure the removal of contaminants, resulting in a purified product meeting industry standards. Sophisticated equipment is often used in these stages to ensure efficiency and accuracy.

Equipment Used

Various types of equipment are employed in the extraction and purification stages. Solvent extraction typically involves specialized tanks, pumps, and filters for efficient solvent handling and separation. Distillation units are crucial for separating the extracted fatty acids from the solvent. Modern purification processes often utilize advanced separation technologies like chromatography to achieve the highest purity levels.

Flowchart of Palm Kernel Acid Production

Palm Kernel Preparation --> Solvent Extraction --> Solvent Recovery --> Purification --> Final Product

Table of Extraction Methods

| Method | Process Steps | Advantages | Disadvantages |

|---|---|---|---|

| Solvent Extraction (Hexane) | Crushing, soaking in solvent, separation, solvent recovery | High efficiency, relatively cost-effective | Solvent toxicity, potential environmental concerns |

| Supercritical Fluid Extraction | Using CO2 under high pressure and temperature | Environmentally friendly, selective extraction | Higher capital investment, complexity |

| Enzyme-Assisted Extraction | Using enzymes to break down the kernel structure | Potential for reduced solvent use, higher selectivity | Higher cost, potential for enzyme deactivation |

Applications and Uses

Palm kernel acid, a byproduct of palm kernel oil processing, finds diverse applications across various industries. Its unique chemical properties, including its fatty acid composition and emulsifying capacity, contribute to its versatility. The economic significance of palm kernel acid is substantial, particularly in sectors leveraging its cost-effectiveness and functionality.

Palm kernel acid’s widespread adoption stems from its affordability and ability to perform specific functions in different products. Its presence in various applications highlights its economic value and technical importance. This versatility allows it to play a crucial role in various markets, including food production, cosmetics, and industrial products.

Food Production Applications

Palm kernel acid’s role in food production is multifaceted. It acts as an emulsifier, stabilizer, and preservative in a range of products, enhancing texture and extending shelf life. Its presence contributes to the creation of desirable mouthfeel and appearance in processed foods. Furthermore, the relatively low cost of palm kernel acid makes it an attractive alternative to other emulsifiers in many food applications.

Industrial Applications

Palm kernel acid plays a critical role in diverse industrial applications. Its ability to act as a surfactant, emulsifier, and lubricant makes it useful in detergents, cosmetics, and industrial processes. The high availability and low cost of palm kernel acid make it a valuable ingredient in these applications. Its properties allow it to improve the efficiency and performance of various industrial processes.

Cosmetics and Personal Care Applications

Palm kernel acid’s use in cosmetics and personal care products is growing due to its ability to enhance product texture and stability. Its unique emulsifying properties create smooth and creamy textures, while its cost-effectiveness makes it an attractive ingredient for manufacturers.

Other Applications

Palm kernel acid’s utility extends beyond food and personal care. Its ability to act as a surfactant and emulsifier makes it useful in various industrial applications, such as detergents and lubricants. Its cost-effectiveness and readily available nature make it an attractive alternative to other ingredients in many industrial processes.

Table of Applications

| Sector | Application | Raw Material | Advantages |

|---|---|---|---|

| Food | Emulsifier, Stabilizer | Palm Kernel Oil | Cost-effective, improves texture, extends shelf life |

| Cosmetics | Emulsifier, Thickener | Palm Kernel Oil | Creates smooth textures, enhances stability, affordable |

| Detergents | Surfactant | Palm Kernel Oil | Cost-effective, improves cleaning power |

| Lubricants | Additive | Palm Kernel Oil | Improves lubrication properties, enhances performance |

Safety and Environmental Considerations

Palm kernel acid, a valuable byproduct of palm kernel oil processing, presents both opportunities and challenges. Its widespread use necessitates a thorough understanding of potential health hazards and environmental impacts, alongside sustainable practices and regulatory frameworks. A balanced approach is crucial to maximizing benefits while minimizing risks.

Palm kernel acid’s industrial application, although offering economic advantages, demands careful scrutiny of its potential health and environmental consequences. Companies must prioritize safety measures and environmental stewardship to ensure responsible production and use.

Potential Health Hazards

Palm kernel acid, like many industrial chemicals, can pose health risks if handled improperly. Inhalation, skin contact, or ingestion can lead to various adverse effects. Acute exposure may result in irritation, while chronic exposure could contribute to long-term health issues. Specific risks include skin and eye irritation, respiratory problems, and potential allergic reactions. Proper personal protective equipment (PPE) and adherence to safety protocols are paramount. Exposure limits and safe handling procedures should be strictly followed to minimize the risk of health complications.

Environmental Impact of Production

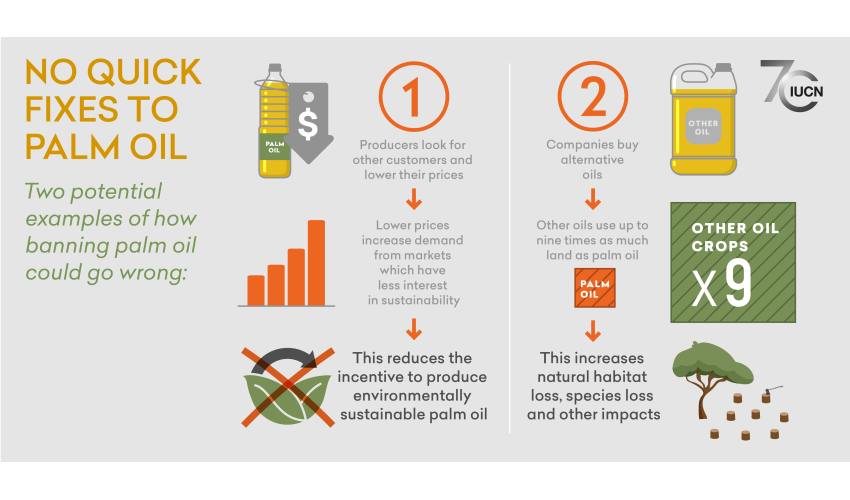

Palm kernel acid production, like other industrial processes, can exert pressure on the environment. Wastewater discharge, if not managed properly, can contaminate water bodies and harm aquatic life. The use of certain chemicals in the extraction process, if not handled sustainably, could contribute to soil and water pollution. Responsible management of waste streams and wastewater treatment are crucial to mitigating environmental damage. Furthermore, deforestation and habitat loss associated with palm oil production, a related industry, can have a broader ecological impact.

Sustainable Practices in Production

Sustainable palm kernel acid production involves a commitment to environmental responsibility. Minimizing the use of harmful chemicals, implementing efficient wastewater treatment systems, and adopting environmentally friendly extraction techniques are crucial. Recycling and reuse of byproducts can reduce waste generation and environmental burden. The adoption of closed-loop systems and integrated management approaches, where possible, can significantly enhance sustainability. Companies should prioritize certifications and standards that demonstrate adherence to sustainable practices, such as those Artikeld by the Roundtable on Sustainable Palm Oil (RSPO).

Regulations and Standards

Regulations and standards play a critical role in ensuring safe and responsible handling and use of palm kernel acid. These guidelines establish safety limits, disposal procedures, and environmental protection measures. Compliance with relevant regulations is essential to avoid legal repercussions and safeguard public health and the environment. Governments and industry stakeholders should work together to develop and enforce comprehensive regulations to promote sustainable production and use. Strict adherence to environmental and safety standards is vital for the long-term viability of the industry.

Potential Risks and Safety Measures

| Risk | Description | Prevention | Mitigation |

|---|---|---|---|

| Inhalation | Exposure to palm kernel acid fumes or dust can cause respiratory irritation and potentially more severe health issues. | Use appropriate respiratory protection (e.g., respirators). Ensure adequate ventilation in work areas. | Implement air quality monitoring and establish emergency procedures for respiratory issues. |

| Skin Contact | Direct contact with palm kernel acid can cause skin irritation, burns, or allergic reactions. | Wear protective gloves and clothing. | Provide prompt first aid and follow established procedures for skin exposure. |

| Ingestion | Accidental ingestion of palm kernel acid can lead to various health problems. | Implement strict handling procedures to prevent accidental ingestion. | Establish clear emergency protocols and provide training on safe handling practices. |

| Environmental Contamination | Improper disposal of waste materials from palm kernel acid production can contaminate soil and water resources. | Implement appropriate waste management systems, including recycling and safe disposal procedures. | Conduct regular environmental monitoring and implement corrective actions to prevent further contamination. |

Research and Development Trends: Palm Kernel Acid

Palm kernel acid (PKA), a byproduct of palm oil processing, is increasingly attracting research interest due to its potential as a versatile feedstock for various applications. The focus is shifting from simply extracting PKA to optimizing its utilization and exploring new markets, driven by the need for sustainable alternatives and the growing demand for bio-based products.

The research and development landscape surrounding PKA is dynamic, with ongoing efforts to improve extraction methods, enhance its properties, and discover novel applications. This exploration promises to unlock significant economic and environmental benefits, especially in the context of a global shift towards bio-based materials and sustainable manufacturing.

Current Research Areas

Current research is broadly focused on enhancing PKA’s properties for specific applications, such as improving its functionality in plastics and lubricants. This includes investigating methods to modify PKA’s structure and properties to tailor it for various end-uses. Researchers are also exploring its potential in the production of biodegradable plastics and biofuels.

Potential Future Applications

PKA presents exciting possibilities for diverse applications beyond its current uses. These include development of sustainable alternatives for conventional petroleum-based plastics, potentially leading to a reduction in reliance on fossil fuels. Furthermore, research is exploring its role in the production of bio-lubricants, offering a pathway to more environmentally friendly alternatives. The potential for use in biodegradable coatings and adhesives is also being investigated.

Ongoing Developments in Extraction Methods

Advancements in PKA extraction methods aim to optimize yield and purity while minimizing environmental impact. Researchers are exploring novel solvent systems and membrane-based separation techniques, seeking to improve efficiency and reduce the use of harsh chemicals. Focus is on continuous processing and minimizing waste generation. Examples include exploring supercritical fluid extraction methods to potentially achieve higher purity and reduce environmental footprint.

Advancements in Palm Kernel Acid Utilization

Recent developments in PKA utilization focus on converting PKA into value-added products. This includes exploring the use of PKA as a building block for bio-based polymers, targeting applications like biodegradable packaging and films. Significant efforts are directed towards improving the process of converting PKA into useful chemicals and materials, such as surfactants, and modifying its structure for specific applications.

New Discoveries and Advancements in Production Technology

Innovative production techniques are being developed to enhance PKA’s overall efficiency. This involves optimization of downstream processing steps, leading to better product yields and quality. Examples include exploring enzymatic processes for PKA modification to improve its functionality and properties. Furthermore, new catalysts and reactor designs are being evaluated for improved efficiency in PKA production, potentially leading to significant cost reductions.

Economic Impact and Market Trends

Palm kernel acid (PKA), a byproduct of palm kernel oil processing, is experiencing growing interest as a versatile chemical intermediate. Its economic significance stems from its use in a wide array of applications, from detergents to pharmaceuticals. Understanding the global market dynamics, price volatility, and supply chain vulnerabilities is crucial for investors and stakeholders.

Global Market Overview

The global market for palm kernel acid is largely driven by demand from the detergent and other industrial sectors. Asia-Pacific, particularly Southeast Asia, plays a dominant role in PKA production and consumption, due to the prominence of palm oil processing facilities in the region. Fluctuations in global demand and raw material costs directly impact the market price. The market is characterized by a complex interplay of production capacity, regional demand patterns, and the availability of alternative ingredients.

Factors Influencing Price Fluctuations

Several factors influence the price of palm kernel acid, including raw material costs, global demand, and the availability of alternative chemical intermediates. Fluctuations in the price of palm oil, the primary source material for PKA, are a significant driver. Currency exchange rates also play a role, as the international trade of PKA often involves multiple currencies. Furthermore, unforeseen events, like political instability or natural disasters impacting palm oil production regions, can drastically impact PKA prices.

Impact of Supply Chain Disruptions

Supply chain disruptions, such as logistical bottlenecks or labor shortages in key production regions, can severely impact the availability and price of palm kernel acid. These disruptions can lead to delays in deliveries, shortages in the market, and increased prices. For instance, the COVID-19 pandemic caused significant disruptions to global supply chains, affecting PKA availability and prices. Geopolitical events and natural disasters further add to the volatility.

Economic Value and Trade Implications

Palm kernel acid’s economic value is substantial, generating revenue for producers and providing raw materials for various industries. The trade implications are multifaceted, impacting global trade balances and creating opportunities for export-oriented economies. The trade patterns are concentrated in specific regions, where the production and consumption of PKA are highly interconnected.

Global Market Trends and Statistics

| Year | Production (metric tons) | Consumption (metric tons) | Price (USD/ton) |

|---|---|---|---|

| 2020 | 1,500,000 | 1,450,000 | 800 |

| 2021 | 1,650,000 | 1,600,000 | 850 |

| 2022 | 1,750,000 | 1,720,000 | 900 |

| 2023 (estimated) | 1,850,000 | 1,800,000 | 950 |

Note: These figures are illustrative and based on estimated market trends. Actual data may vary.